Citation: Nordy R, “Complexity of Patch Pump Assembly and Considerations for Mastering It”. ONdrugDelivery, Issue 124 (Sep 2021), pp 22–25.

Roger Nordy discusses the complexities of patch pump assembly and explains how ATS has been mastering the intricacies of the automation process to take on the growing industry demand.

According to a May 2021 report published by Fortune Business Insights, the patch pump market is expected to grow from US$3.62 billion (£2.64 billion) in 2020 to nearly $11.86 billion by 2028 – representing a 16 % compound annual growth rate (CAGR) from 2021-2028.1 While a rise in the number of diabetic patients globally factors into this anticipated increase in demand, so too does the high degree of convenience and peace of mind patch pumps bring to users.

“Patch pumps, while relatively small devices, are highly complex.”

Instead of the traditional multiple daily injections (MDI) method of insulin delivery to maintain blood sugar levels, there is now an alternative. Patch pumps that are filled by the user, adhered to the skin and paired to a specific customised diabetes management device (much like a handheld device or mobile phone) can provide insulin delivery for more than two days.

This means patch pump wearers no longer experience several needle pricks daily, providing huge relief not only for the user, but also for the caregivers of infants, children or other patients incapable of self-administering insulin. Furthermore, when paired with a suitable glucose monitoring device, blood sugar levels can be continuously monitored. And, while a device that can act as an “artificial pancreas” may still be years away, patch pumps could play a key role in the development of this technology.

While the patch pump market is certainly expanding, the process of getting a patch pump (Figure 1) from the drawing board into the end-user’s hands is quite lengthy. Today’s patch pumps are easy to use, quite discrete, smaller than a minicomputer mouse and contain dozens of internal components that need to work harmoniously together every single time they are adhered to the patient’s body. They are life-saving devices and could result in tragic consequences if they aren’t functioning properly.

Figure 1: Patient using a patch pump for insulin delivery.

SIZE MATTERS

“If parts aren’t consistent, it will likely have a profound effect on overall manufacturing efficiencies.”

Patch pumps, while relatively small devices, are highly complex – and when a company looks to assemble and test these devices on their own production floor using automation, they must partner with a company that can manage and execute these huge programmes from beginning to end. As a result, automating the assembly, testing and pack-out is equally complex. Often, very large, integrated automation programmes occupy an entire production plant’s floor space.

Putting together dozens of components in one single device requires multiple systems cascading finished sub-assemblies from one assembly cell to the next. Essentially, what you are doing is building sub-assemblies and those sub-assemblies need to then be routed and introduced into the next system – and even the smallest nuances of change within each sub-assembly need to translate to the next sub-assembly. The entire system needs to be thoughtfully engineered and material flow must be co-ordinated perfectly, but it also needs to be flexible enough to minimise downtimes across the entire production system. Simply stated, with a highly complex system like this, a single poorly performing cell can bring the whole production line to a halt.

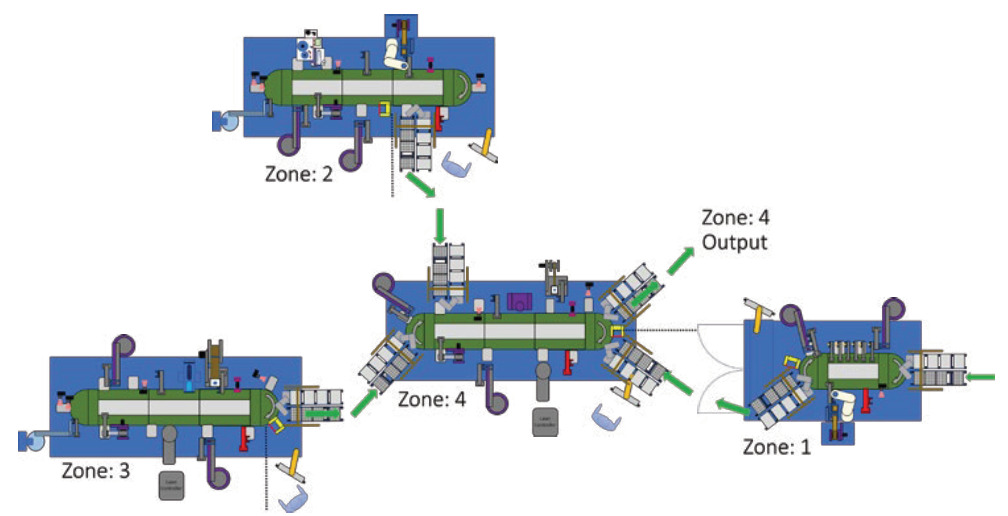

Imagine Zone 1 is building Widget A, Zone 2 is building Widget B and Zone 3 is building Widget C. All three of those widgets are then input into Zone 4, which is building Widget D and which then feeds into another zone and so on. For any number of reasons, when there is variability within Zone 1, the output of widget A is affected which, in turn, will affect Zone 4’s performance. If you must make an adjustment in Zone 1, you might also then have to deal with the outcome of that adjustment in Zone 4 because of the newly introduced variation. This leads to a continuum of back and forth to dial in the process.

INTEGRATION CONTINUITY IS PARAMOUNT

If you were to look at a sub-assembly’s flow through the system, it would quickly become apparent that the likelihood of success is linked to an integrator’s ability to design, build and integrate the entire programme on their floor prior to shipment. If the integration of the equipment is attempted on-site at the production facility, the programme will likely be stalled – perhaps even to the point that you may never get the production line running.

Due to the complex nature of these types of systems, their massive footprint and the sheer number of some of the industry’s brightest minds required to integrate them, ATS is a logical fit for patch pump manufacturers. Its production floor is staffed with over 1,500 people in the Life Sciences division alone, with a global network of suppliers and services.

“A successful patch pump programme is a true partnership between the customer and the automation supplier.”

VALIDATION STARTS AT THE DESIGN PHASE

A well-organised and comprehensive validation package is of paramount importance – and is something that regulatory agencies around the world expect. Equipment validation begins with the user requirements specification (URS). With a programme as complex as a patch pump, continuing the equipment validation effort through from the very first steps of the design phase is only logical. It ensures that overall programme continuity is maintained, simplifying the process by gathering the relevant information along the way, and saving costs and efforts in the end. Engaging the dedicated ATS validation team at the programme’s conception, even if it is just for a risk-based validation approach, puts the customer on a time- and cost-saving path to production.

FEEDING AND PART CONSISTENCY IS KEY

To state the obvious, automation will not work if you can’t get the parts to the line. There are a plethora of different feeding technologies, each of which can and does take on many different form factors and commercial profiles. Effective feeding systems are essential to the success of any automation programme. The more complex the programme, the more influence (good or bad) that feeding will ultimately bring to the production floor.

Whether the parts are introduced to the line in trays, reel format, from bulk or by some other means, you must find a way to consistently get each part isolated so that it can be picked up reliably and be ready for further processing. As an example, if one of the multiple dozens of parts changes, even only slightly, it could cause performance issues within that station.

Consider the diagram in Figure 2 – a part inconsistency within Zone 1 may cause Zone 1 to struggle to run and, as a result, it will have a cascading ripple effect of struggles that will be passed along to Zone 4 and each subsequent zone after that, and therefore will affect the entire assembly and test system. Bottom line, if parts aren’t consistent, it will likely have a profound effect on overall manufacturing efficiencies.

Figure 2: Zone sketch example of patch pump automation.

To address some of the incoming material inconsistencies and mitigate those risks, ATS recommends a series of proof of principal (POP) tests and a customer component tolerance stack-up/ review by looping in different suppliers for the different components. It is about understanding how the components work together while learning what works and eliminating early what doesn’t.

Figure 3: The ATS SuperTrak CONVEYANCE™ platform (A) and the Illuminate™ Manufacturing Intelligence software (B).

THE RIGHT TECHNOLOGIES

Over the last few years in the life sciences space, ATS has received automation requests for devices that are becoming more and more complicated. To address these challenges, innovative turnkey solutions with high modularity, scalability and customisation have been the key to the company’s success. This starts with special feeding and handling technologies that move parts through flexible conveyance platforms and high-end assembly solutions to effective tray/pallet handling and packaging automation.

For patch pumps with 40 or more components, continuous functional and vision testing stations after almost every process step are essential. Due to the large footprint of these programmes, which can stretch out over various production halls, material transport also needs to be innovative. And, last but not least, manufacturing intelligence is required that is able to capture subassembly, finished product, and machine performance data over the entire production system – with artificial intelligence to avoid downtimes, react flexibly, recognise real time risks, carry out predictive maintenance and capture all kinds of analytics from each station (Figure 3).

COLLABORATION FROM DAY ONE

While ATS has the tools and technologies to successfully complete a patch pump programme, it’s not enough. The reality is projects don’t finish themselves. You must drive them to completion.

A successful patch pump programme is a true partnership between the customer (or end user) and the automation supplier. ATS’s project management team leverages PMI PMBOK-based principles and is a group that is focused on success. The team works in tandem with the customer on a daily basis, combing through multiple design reviews of each part of the automation. A transparent cross-company project management tool with hundreds of tasks and subtasks tracks the project’s progress and any upcoming risks, delays or issues – making everything visible for everybody and defining exact responsibilities.

The customer plays a huge role in the programme’s success. These programmes are a true collaboration, with each team bringing their own knowledge, tools, answers and experiences, and then openly sharing this knowledge. Over the many months of a project like patch pump assembly, the lines between the teams may become a bit blurred, but that begins to tell the story of the collective single path to success.

INSULET’S AUTOMATION PARTNER

In September 2016, Insulet publicly announced that ATS was its automation partner for its OmniPod pump.2 This was part of a multi-year, multi-million-dollar programme.

“Utilising cutting edge technology, we will produce our product at the highest quality, and lowest cost in the industry,” said Insulet in a promotional video for its new, world-class manufacturing facility in Acton (MA, US).3 “These new unrivalled, automated production lines will directly address many current challenges in production. The automation will also drastically reduce needed labour resources and mitigate the risks associated with having a single source supply chain.

“Our product is highly complex and, as such, we need to utilise the most advanced and capable technology and talent,” the video continues. “Our highly automated operation will accelerate the efficiency of our global manufacturing operations and supply chain and allow us to adapt to market conditions and innovate faster than our competitors.”

ATS continues to work with Insulet today.

REFERENCES

- “Insulin Pump Market Size, Share & COVID-19 Impact Analysis, By Product Type (Pumps (Tethered Pumps, Patch Pumps, Others) and Consumables); By Disease Indication (Type 1 Diabetes, and Type 2 Diabetes), By Distribution Channel (Hospital Pharmacy, Retail Pharmacy, and Online Stores) and Regional Forecast 2021-2028”. Fortune Business Insights, May 2021. (Accessed August 9, 2021, https:// www.fortunebusinessinsights.com/ insulin-pump-market-102735.)

- Densford F, “Insulet taps ATS Automation Tooling for planned U.S.plant, beefs up executive suite”. Medical Design & Outsourcing, Sept 2016.

- Omnipod video. Insulet Acton Facility, Jan 2019.