To Issue 153

Citation: Natarajan P, Bavar S, Dean C, “How Lifecycle Assessment Supports Insight-Driven Sustainable Design”. ONdrugDelivery, Issue 153 (Oct/Nov 2023), pp 16–19.

Paramesh Natarajan, Shadi Bavar and Charlie Dean present the case for using screening lifecycle assessments to lead into more detailed targeted and comprehensive lifecycle assessments focused on the areas of greatest environmental impact, using a screening lifecycle assessment of a hypothetical body-worn injector as an example.

Drug delivery devices will play a pivotal role in achieving the UN’s sustainable development goal of good health and wellbeing for all. This is true for body-worn injectors, which ensure consistent and accurate dosing of essential medicines over long periods of time while granting patients the freedom to conduct their usual daily activities. However, despite their benefits, they can have a high environmental impact due to their complex and short-use-life componentry. At a time when climate change is a top priority, is it possible to develop safe and effective drug delivery devices, including body-worn injectors, with a reduced burden on the environment?

“The goal of a screening LCA is to identify the biggest environmental impacts in a product’s lifecycle and use them to inform strategic decisions early in the design process.”

When considering the environmental impact mitigation of a drug combination product, the first requirement usually focuses on maintaining or improving clinical efficacy and patient safety. The second is often around achieving equivalent or lower cost. At first glance, these two requirements can seem to prohibit sustainable initiatives. Whilst challenging, sustainable device innovation is more likely to succeed with a rigorous and insight-driven approach. Lifecycle assessment (LCA) is a methodology that has been developed to achieve just that.

LCAs are a comprehensive, data-driven and systematic approach to uncover the greatest opportunities to reduce environmental impact, which can often be counterintuitive. This article outlines a screening LCA on a conceptual body-worn injector to identify hotspots and opportunities for mitigation. It also aims to uncover different levels of LCA and when best to use them.

TYPES OF LCA

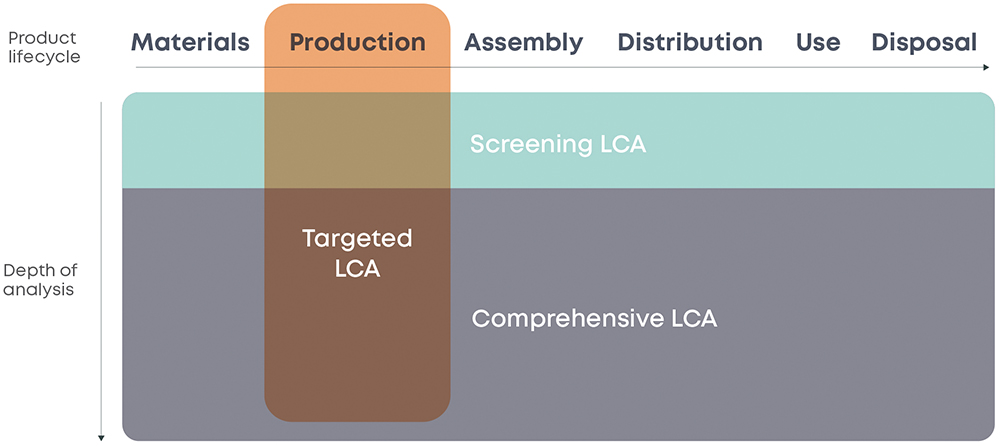

Conducting an LCA is often considered a burdensome and costly exercise. When assessing the full lifecycle, numerous data sources, and thus data owners, are required. In most cases, the types of data required are not even typically measured or reported. Commissioning an assessment for the first time with the expectation that it will be fully comprehensive for public marketing claims will likely result in a long, drawn-out process, as engaging with every stakeholder for the first time to request relevant data will be prohibitively time consuming. Fortunately, the LCA framework can be adapted to suit different levels of investment and commitment for different applications (Figure 1). Understanding how to scale LCA rigour is key to making the most out of the initiative to target ambitious sustainability goals.

Figure 1: Types of LCA.

SCREENING

The goal of a screening LCA is to identify the biggest environmental impacts in a product’s lifecycle and use them to inform strategic decisions early in the design process. As such, the approach should be a top-level sweep of a full lifecycle, focusing on relevant impact categories, such as global warming, water usage and ozone depletion. Given this high-level approach, when populating the lifecycle inventory (LCI), the analyst will need to make broad assumptions about processes and components. This may include using existing devices as a template for material choices, material quantities, assembly locations, etc. This may also include use of market average data from existing databases, such as EcoInvent, rather than primary data specific to the product in focus.

The benefit here is a quick turnaround on getting results and a low reliance on data fidelity, but great care must be taken when interpreting results, given the level of uncertainty around the inputs. The output of a screening LCA can provide valuable and timely insight to guide system architecture but should not be used to make competitive market claims.

TARGETED

During the development process, the screening LCA is just the first step towards quantifying impacts. It is important to refine the model further and improve confidence in the screening LCA’s results. The goal of the targeted LCA is to make focused optimisations to the product’s design by taking a detailed approach to a particularly impactful area identified by the screening LCA. As such, the scope is limited to perhaps a single component or module, or maybe a particular process, such as the transport impacts from one site to another. Targeted analyses should be conducted in close collaboration with the relevant stakeholder to ensure efficient knowledge and data sharing; for example, with the product design and engineering team for gathering data on materials and manufacturing processes.

COMPREHENSIVE

When progressing through the design process, targeted analyses should be conducted on differing areas to increase confidence in areas of high impact, shed light on unknown areas of impact and further optimise the design. Naturally, what started as a screening LCA starts to look increasingly comprehensive through these targeted analyses. By the point a comprehensive LCA has been done, it is likely that only fine-tuning optimisation can be carried out. As such, the goal of a comprehensive LCA is often to get an accurate impact assessment that can be reviewed and published externally. As with the screening LCA, the scope is broad, but at a vastly increased level of detail and fidelity, where the LCI could be the combination of preceding targeted LCAs.

SCREENING LCA OF CONCEPTUAL BODY-WORN INJECTOR

Goals

- Illustrate the merits and accessibility of the screening LCA, while also highlighting the limitations

- Identify environmental burden hotspots and propose recommendations for well-targeted mitigations.

Scope

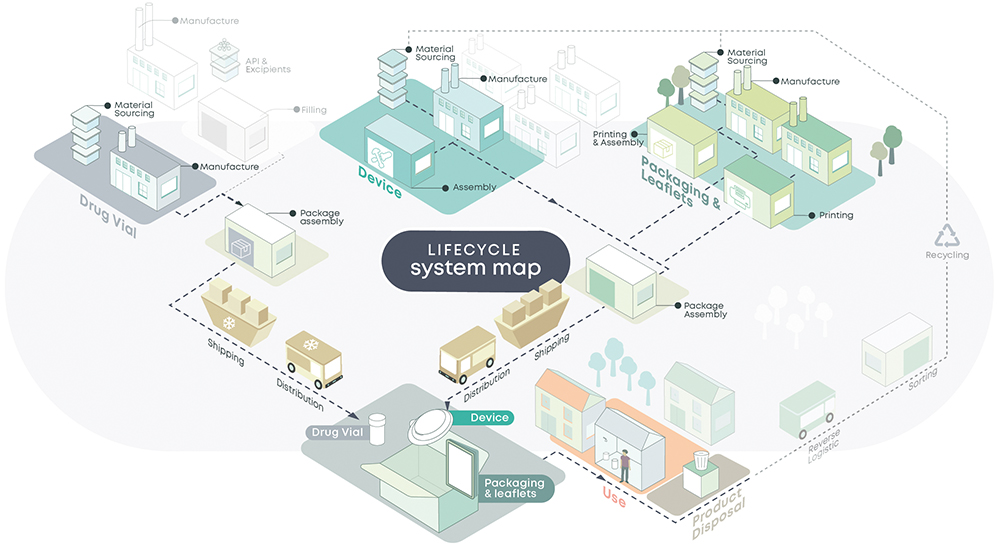

High-level impact assessment of a conceptual disposable body-worn injector, from raw material extraction through to disposal (cradle to grave). The whole system map shows the breadth of the lifecycle in scope, as well as an approximation of the level of fidelity included in this screening LCA (Figure 2). High-level assumptions were made to give an indication of the impact associated with every relevant process throughout the product’s lifecycle. Mapping in this way can enable easy visualisation of the supply chain.

Figure 2: Lifecycle system map of conceptual body-worn injector.

Lifecycle Inventory

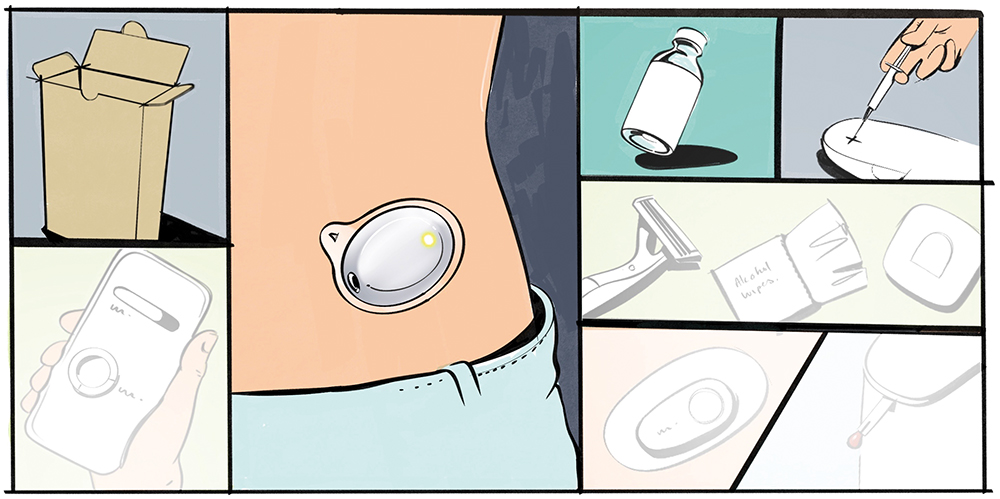

The product system includes mechanical componentry, casings, electronic systems, wiring, batteries, the drug primary container, needles, syringes, packaging and instructions for use (Figure 3). Notable exclusions include the drug formulation, at-home drug refrigeration, consumables associated with site preparation and a companion smartphone or similar device. The drug product was excluded due to variability in formulation and therapeutic area, and the monitoring devices were excluded due to variability in product embodiment and classed as an accessory to a broader product system. Given that the LCA is at a screening level on a conceptual device, market average lifecycle inventory data from the EcoInvent 3.9 database was used for the processes, materials and components used.

Figure 3: Product system inventory, with out-of-scope items greyed out.

IMPACT ASSESSMENT

The results of the screening LCA are calculated for over 20 impact categories quantifying environmental impact in a variety of specific sectors, from which the most relevant can be focused on in greater detail. Each category aggregates contributions toward a specific impact and quantifies them using a single unit; for example, global warming is reported in mass of CO2 equivalent and represents not only direct carbon emissions, but also other sources of global warming, such as methane and nitrous oxide. Other impact categories include fine particulate matter formation, soil acidification, waterway eutrophication, human toxicity, land use, water use and energy use.

The results of an LCA are versatile and can offer insights beyond the relative contribution of each element of the device or lifecycle to an impact category. The components of the device can be grouped as needed to compare the impact of functional submodules, types of materials, lifecycle stages or even manufacturing processes.

INTERPRETATION

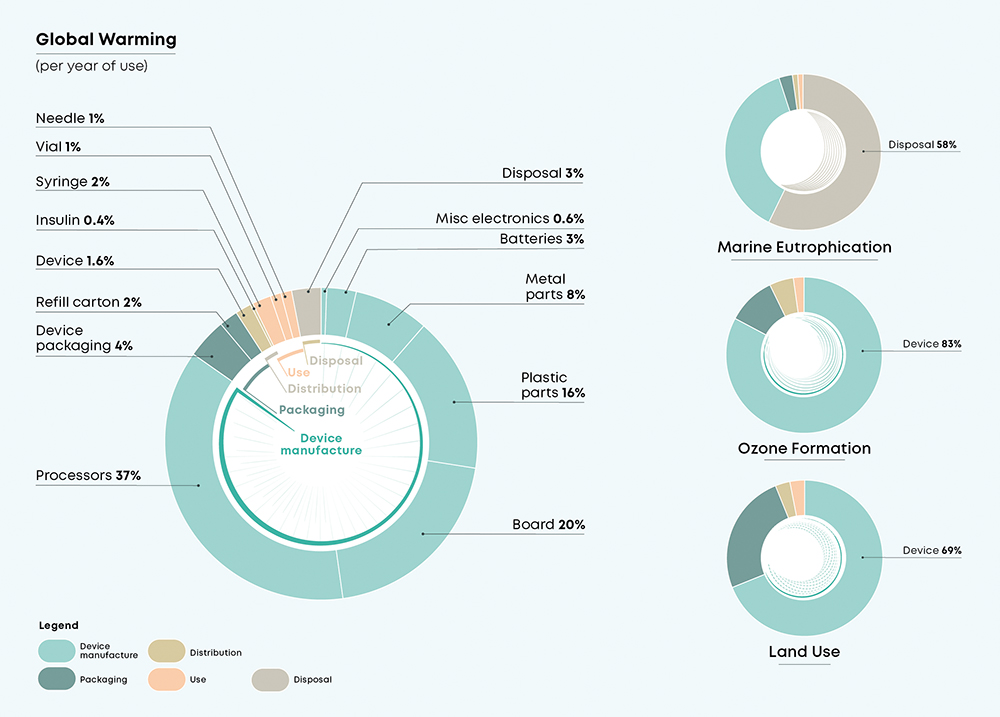

Due to the nature of a screening LCA, the absolute values are not reported to prevent any comparison to published comprehensive analyses conducted at a deeper level. However, key insights may still be drawn from the distribution of impacts.

The results revealed that device manufacture represents 75–95% of the environmental impact across all categories but one (Figure 4). Taking global warming as a representative example, two thirds of device impact are due to the printed circuit board and integrated circuit chips, which have a high demand for electricity during manufacture and extraction of raw materials.

Figure 4: Screening LCA results of conceptual body-worn injector.

The remaining stages of the lifecycle – packaging, distribution, use and disposal – have remarkable impacts in only one or two categories each. The most significant contribution of packaging is in land use and ozone depletion, where it makes up approximately 25% of the lifecycle impact in those categories. The land use is primarily caused by manufacture of integrated circuit chips, boxboard shipping cartons, printed circuit boards and metal components. Distribution has relatively low impact across all categories but makes the most significant contribution towards ozone formation (10%) – the impact comes from container ship transport, not only of the final product, but also of the copper and gold used in the printed circuit board assembly manufacture. There was no significant contribution from use in any category.

Finally, product disposal has a high contribution to marine and freshwater eutrophication (60% and 40%). It is possible that this is due to municipal solid waste disposal, notably treatments of waste plastic mixture.1 This observation highlights the limitation of relying on market average LCI data, in this case EcoInvent, as it is not known if this deviation from the trend is accurate. Further investigation into plastic waste processing for landfill would be advisable in follow-up targeted analyses.

STUDY SUMMARY

The printed circuit board assembly emerged as the most influential component across the range of impact categories, making it a prime candidate for mitigating environmental impact. The results indicate that implementing ways to reuse the electronics has the potential to significantly reduce the impact of device manufacture.

It is important to rely on data-driven analysis, rather than gut-feel assumptions, to identify targets for design change. This concept is underscored by some unexpected results of this LCA – the batteries did not appear as significant contributors, perhaps counterintuitively, despite their large mass and rare metal components. Distribution, including refrigerated cold-chain storage of the drug product, also had lower impact across a range of categories than expected.

Lastly, when leveraging the results of a screening LCA to drive decisions or engage with stakeholders, it is key to offer sufficient context around the limitations and assumptions made. In this case, this LCA was used for educational purposes on a conceptual device and may not accurately reflect results for products on the market.

CONCLUSION

Despite its limitations, conducting a screening LCA is a valid and valuable exercise to begin strategising on sustainable drug delivery device transformation. The alternative approach of committing significant investment based on opinions or trends in sustainability is far less likely to lead to successful sustainable device development. The LCA framework is flexible enough to allow for scaling the level of analytical rigour to suit the application. Starting early in development with a screening LCA will ensure that development teams are more aware of sustainability objectives, more likely to measure and report relevant data, and prime partners throughout the supply chain to engage with the process to pave the way for targeted and comprehensive analyses to follow.

REFERENCE

- Vlasopoulos A et al, “Life cycle assessment of plastic waste and energy recovery”. Energy, 2023, Vol 227, Article 127576.