To Issue 159

Citation: Jost R, Kalbermatter G, “Interview: the Benefits of Being an Early Adopter of Sustainability Principles”. ONdrugDelivery, Issue 159 (Apr/May 2024), pp 6–10.

“While we work to maximise our own carbon reductions, it’s just as important for the whole supply chain – the partners around us – to be moving in the same direction.”

Q Ypsomed was an early adopter of sustainability principles – one of the first in the devices sector. In your opinion, what are the advantages that recognising the importance of sustainability early brings and can you describe some of the key learnings you’ve made along Ypsomed’s sustainability journey?

A In 2016, Ypsomed committed to a consistent improvement in energy efficiency and introduced reforesting and regeneration programmes. . As a company which thinks long-term, sustainable action has always been one of our basic principles. Since the integration of sustainability in our corporate strategy in 2020, we consider sustainability holistically within all business activities and business units. Sustainability initiatives take time to bear fruit, so starting early has given us additional time to prepare and see how our programmes are progressing.

The key benefits from our perspective have been learning where the most potential to improve the sustainability profile of our products is – what we have to work on, where we can do better. Ypsomed initiated its NetZero Program in 2020 (Box 1), starting with projects to minimise the carbon footprint of our existing products.

BOX 1: YPSOMED’S NetZero Program

– By 2030: Net-zero operational CO2 emissions (Scope 1 & 2)

– By 2030: A selection of products meet net zero GHG emissions across their individual value chain (Scope 1–3)

– By 2040: Net-zero CO2 emissions across Ypsomed’s entire value chain (Scope 1–3).

– Using waste heat from production to reduce gas consumption

– Using the latest generation of energy-efficient machines for injection moulding

– Using 100% renewable electricity

– Employing innovative building technology for optimised heating, cooling and ventilation.

– The Alliance to Zero was founded in 2021 by Ypsomed and seven other companies along the pharmaceutical value chain

– The Ypsomed Sustainability Academy facilitates internal and external networking designed for training and awareness raising on the topic of sustainability

– Ypsomed supports a selection of high-quality global climate protection projects, including forest conservation measures in Brazil and Kenya and a reforestation project in Tanzania.

BOX 2: YPSOMED’S ECODESIGN GUIDELINE

Ypsomed’s ecodesign guideline comprises seven key sections, which provide definitions and guidance on how to apply sustainability principles to different aspects of product development at Ypsomed:

- Ypsomed’s sustainability goals

- Objective and application

- Concept check

- Material selection

- Lifecycle assessment

- Packaging

- Disposal and recycling.

It has taken time working with suppliers to ensure that they contribute to reducing the carbon footprint of our products. A really key learning was when we realised that, while we work to maximise our own carbon reductions, it’s just as important for the whole supply chain – the partners around us – to be moving in the same direction. That was one reason why we became a founding member of the Alliance to Zero in 2021 (Box 3).

BOX 3: THE ALLIANCE TO ZERO

Additionally, with a highly regulated industry like pharma, you inevitably have resistance to change. This is especially true where you have established products, where any change is associated with a lot of work in terms of testing, documentation and re-registration. Then you have all the regulations in terms of chemical components and composition to consider when sourcing materials, which means that you don’t have the same freedom to replace some of the materials with lower carbon footprint alternatives that you would have in a less regulated industry.

“A major part of ecodesign is building in circular economy thinking – closing the circle to recycle products and materials and to develop new business models that are even more sustainable.”

Q In Ypsomed’s view, is sustainability purely about CO2 or are there other factors you consider? Also, can you explain the principle of ecodesign in more detail?

A In terms of corporate sustainability, the meaning is very comprehensive. It includes society, it includes our employees – it isn’t limited to only reducing the environmental impact. It’s about a holistic, sustainable journey that we want to take moving forward. On the product side, however, it is mainly about CO2 in the plastic materials used because that’sthe primary way we have to reduce our environmental impact. Our processes are energy intensive, but we have a range of measures to generate green electricity and recycle energy within our manufacturing plants.

We have set goals to meet net-zero operational CO2 emissions (Scope 1 and 2) in our operations by 2030 and over the whole value chain by 2040. We are committed to a science-based reduction pathway in accordance with the Science Based Target Initiative (SBTi). Our targets were successfully validated by the SBTi at the end of 2023 and it is important to mention that these goals are for all greenhouse gases combined, measured as a CO2 equivalent.

As to ecodesign, the idea is to design our new products in a way that is as eco-friendly as possible. To achieve this, we carried out lifecycle assessments (LCAs) where we calculate the CO2 footprint to enable comparison between concepts or products and give us some hard numbers to work with. It’s a complex problem, but we try to make it more tangible by comparing CO2 equivalents. Also, a major part of ecodesign is building in circular economy thinking – closing the circle to recycle products and materials and to develop new business models that are even more sustainable.

Ecodesign is a guideline that informs how everything is analysed based on standard methods and contains tools and concepts that can help us develop better products. The intent is to increase awareness within the company, to make sure that each and every development team implements ecodesign principles.

Under our ecodesign guideline, we assess risks, costs and sustainability throughout development. All our teams need to be able to present where they stand in terms of sustainability, whatever phase of a project they’re in. The ecodesign guideline is embedded throughout product development – it’s not optional, it’s an integral part of the process.

Q How long have Ypsomed products been developed according to your ecodesign guideline?

A We developed the first draft of the ecodesign guideline in 2021. It has been updated since then, of course, but that’s where we started using it in the development process. Before that, we had lots of ideas, lots of inputs, but nothing written down. Now, it’s concrete – it’s a specific document, with our own experience combined with some more broadly established tools, such as the circular economy and “rethink, refuse, reuse, reduce, repair, recycle” (Figure 1).

Figure 1: The six “R”s of ecodesign – rethink, refuse, reduce, reuse, repair and recycle.

For a device engineer at Ypsomed, as an example, the ecodesign guideline is a part of their daily workflow. Then, for every milestone or design review, there’s a checklist – the ecodesign index – where we have an extensive set of sustainability factors, and we make sure they’ve all been considered during development. However, no one is expected to undertake this alone; everyone is able to keep in close contact with the experts and with colleagues from all our other projects. We can always ask for advice and hold workshops or meetings with someone who can help. On top of that, we have the Sustainability Academy at Ypsomed, where employees receive regular training. Finally, under the ecodesign guideline, a critical part of every development process is an LCA that includes a calculation of the product lifecycle’s expected CO2 emissions according to the standards. We have a dedicated team for this, so it’s always the same group performing these calculations. This ensures that not only are all the calculations done according to the standards, but also that there is comparability between products. This consistency is important.

Q I’d like to go into more detail regarding Ypsomed’s ecodesign LCAs – what are the key inputs and what have you learned from conducting them?

A What we’re doing is calculating cradle-to-gate emissions, from the raw material to when the products leave Ypsomed. This includes all the materials and our own manufacturing but excludes some of the carbon-intensive aspects of the combination product – production of the API, for example. These factors can vary a lot depending on the product, such as whether it requires cold-chain storage or not, or the markets that the product is going to. So, we mainly focus on the activities that Ypsomed is directly involved with, those that we can influence directly.

From this, we’ve seen that the biggest potential for reducing our CO2 emissions is in materials – mainly plastics. After that, the next biggest area for improvement is packaging and production. Then, the last significant one is transport. Based on this, our first step has been to focus on those key areas. Plastics are a particular area we’re focusing on; some of them have significantly greater carbon footprints than others, so we are able to make major reductions to our CO2 emissions.

Q As a specific example of Ypsomed’s ecodesign guideline in action, can you tell us about the development of the Ypsomate 5.5 mL autoinjector from a sustainability perspective?

“We’ve seen that the biggest potential for reducing our CO2 emissions is in materials – mainly plastics.”

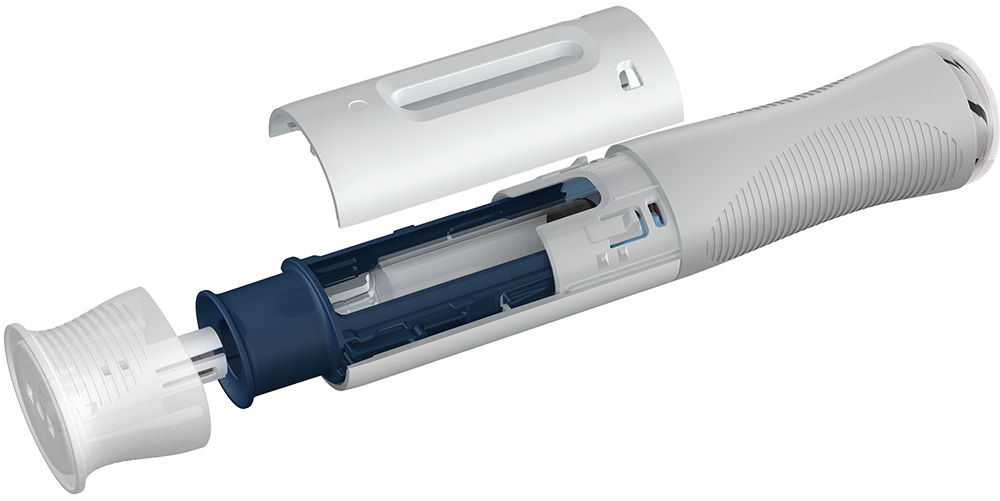

A We started development of Ypsomate 5.5 mL (Figure 2) in 2021, with the aim of designing an autoinjector for larger volumes. A capacity of up to 5.5 mL is very large for an autoinjector, but we were seeing more and more requests for larger volumes, so we felt that it was important to have a platform that could handle them. For example, if you look at oncology and the treatment of rare diseases, there is an increasing need for higher payloads.

Figure 2: The Ypsomate 5.5 mL large-volume autoinjector.

We saw a similar trend when we introduced 2.25 mL autoinjectors in 2016, which have been very successful, and we also have several years’ experience working with the YpsoDose 10 mL patch injector. So, based on that context, we concluded that there was a clear space for a larger volume autoinjector in the market. That was the starting point.

As a positive coincidence, the ecodesign guideline was established around the same time, so we were able to factor in sustainability when designing YpsoMate 5.5 mL from the very beginning in a way we couldn’t with previous products, where we had to bring it in later in the development process. We made sustainable choices from the very first concepts, where we had to choose which mechanism we wanted to use, how complex it should be and what features we wanted to include in the device. We were able to estimate the CO2 emissions for each concept and compare them.

The next important step from a sustainability standpoint was the evaluation of what materials to use. There, we made an estimate for an LCA of all the individual parts. In particular, we looked at the larger parts – those with a higher volume or mass. We focused on selecting materials with the best sustainability profiles. And, after the first set of prototypes and injection-moulded parts, we were able to perform some further optimisations where we reduced the number of parts and their volume.

Another important consideration was the packaging. We sought to design the device in a way that it would take up the smallest possible volume during transport, with the packaging as dense as possible. We ship all our YpsoMate autoinjectors as one subassembly in a single-tray configuration with the syringe holder and power pack “pre-snapped” together. This saves an enormous amount of space and tray material for transportation, which noticeably reduces the carbon footprint associated with transport per device. Along with that, we used more sustainable packaging materials where possible, such as using recycled polyethylene terephthalate (PET) instead of virgin PET. The tray material makes up a significant proportion of the overall plastic CO2 footprint of the autoinjector.

Throughout development, the ecodesign index really helped to guide us. Whenever we reached a key milestone or had a design meeting, we were able to go through the whole device, sometimes part by part, and ask ourselves how well we’d adhered to each aspect of the guideline. This approach helped us make sure that we were keeping sustainability in mind during the design process.

Q How does Ypsomed balance its obligations regarding sustainability with its equally important obligations to maintain impeccable quality and to control costs?

A Clearly, every device has to meet regulations; we need to pass the requirements of ISO 11608 and the regulatory agencies of the target market. In practice, there’s little to compromise on. Obviously, safety and quality standards must never be compromised.

But the reality is that pursuing sustainability is often the opposite of a compromise. Improving sustainability often improves the product overall. For example, cost – while one might expect sustainability and cost to be in conflict, they typically are not. A large part of sustainability is about reducing waste and reducing material use, which also keeps down costs. In practice, sometimes a more sustainable design is more cost efficient because you’re trying to reduce the number of parts and the amount of material used in the device. Usability also affects sustainability, as a lost dose because of a user error is also a loss in terms of CO2.

Usability, cost and quality – these perspectives need to be considered, even if some of them are difficult to quantify.

Q Do you think anything further can be done to improve the sustainability of older devices, or should the focus on sustainability be kept to future products?

A We’ve done a lot of work on optimising Ypsomed’s existing portfolio – it can be done. And doing so is important because drug products have a long lifetime on the market. So, it makes sense to optimise existing products. However, there is probably greater potential for making a device sustainable with new developments.

We still see a lot of potential where we could do better or where we could improve. There’s a lot going on at Ypsomed on this front, especially for end-of-life considerations, such as recycling or refurbishing. And it’s throughout the whole value chain where improvements can be made, not only in product design but also within manufacturing and the supply chain.

In particular, we believe that the industry still needs to adopt more and further develop take-back and recycling solutions .

In particular, we believe that the industry still needs to adopt more and further develop take-back and recycling solutions . There need to be take-back systems that cover all medical devices containing recyclable materials. If the pharma industry does not implement such systems on its own or in collaboration, then regulations will be introduced by national and international authorities.

Another thing to consider on this front is biopolymers; one of the primary ways we have for making existing products more sustainable is to replace their materials with equivalents from renewable sources. As long as the renewable materials are chemically identical to the current material, a switch is relatively simple. The number of product platforms available in the Ypsomed NetZero Program is increasing, maintaining biocompatibility, functionality and safety, with no additional testing required. However, if a polymer is changed, the process is more complex. We’ve now implemented processes to source renewable materials and to feed them into our manufacturing processes.

Q Lastly, what do Ypsomed’s ecodesign guideline and your sustainability initiatives mean for your pharma partners and customers? Do you have any feedback from them, and can you give a sense of the general feeling from pharma about Ypsomed’s efforts?

A For large pharma companies, sustainability is very important and included in the device selection process. When we enter detailed discussions, we have to be able to explain our processes and objectives clearly. Overall, we are making good progress, which has been well received across the industry. Ypsomed is keen to stay ahead of the game and keep pushing on down the path to net zero that we’ve set out for ourselves.