To Issue 165

Citation: “Interview with Glenn Svedberg, Nolato Group”. ONdrugDelivery, Issue 165 (Sep/Oct 2024), pp 26–29.

In this exclusive interview with ONdrugDelivery’s Guy Furness, Glenn Svedberg engages in a wide-ranging discussion around the role and importance of sustainability in the drug delivery industry, and how Nolato Group has approached implementing this critical aspect of the modern industry landscape. Mr Svedberg considers how sustainability factors play into the relationship between CDMOs like Nolato and pharma companies, the importance of materials and how to drive forward sustainability goals within pharma and drug delivery.

Q Many of our readers will be familiar with Nolato already but, for those who might not be, could you provide an overview of the company – in particular, its offerings that are relevant to the drug delivery industry – and a brief overview of your career and current role there?

A Put simply, Nolato is an international solutions provider within polymer-based materials. Our offering spans the entire value chain, including sourcing, moulding, assembly and full-box build, with capabilities covering the full spectrum from development to high-volume production. We always work in close partnership with our customers. We don’t offer many platform products, so we primarily produce custom products. We have 26 sites and four technical design centres across 10 countries, and we support innovative and sustainable products of tomorrow. About 50% of Nolato’s revenue comes from its Medical Solutions division, which is primarily engaged in in vitro diagnostics, drug delivery and medical devices.

As to my role, I’ve spent my whole career working in manufacturing companies across a variety of different industry segments, including heavy vehicles, telecoms, electronics and rigid food packaging. But, for the last 17 years, I’ve been with Nolato Medical Solutions, working as a Managing Director for a variety of companies within Nolato Group, and later coming to drive our medical excellence initiative globally. Today, I’m the Group’s Sustainability and Technical Director, responsible for our sustainable development and technical design centres. I report to our CEO and I’m part of the executive management team.

The non-medical business is called Engineered Solutions, and we work with a number of different industry segments under that umbrella. However, within that, we focus on some specific areas, including telecoms, automotive, hygiene products and gardening equipment, to name a few examples – it’s a quite wide range of segments and products.

Q How does having operations across the world and in a range of diverse industries give Nolato useful insights into sustainability as it applies across geographic areas and industry sectors to different products and technologies?

“When it comes to adapting for sustainability, we know change is always a headache for the medical sector, due to regulatory compliance and validation, which often means slower development – the medical sector is usually a few steps behind.”

A There are different drivers in the various industries. Before I jump into sustainability, it’s worth mentioning that different industries have significantly different priorities. For example, for consumer electronics and those sorts of products, it’s all about speed and innovation. For automotive, on the other hand, their focus is on lean manufacturing and optimised cost. And, as I’m sure you know, the medical sector’s top priority is quality and consistent processes, which can lead to a resistance to change. So, when it comes to adapting for sustainability, we know change is always a headache for the medical sector, due to regulatory compliance and validation, which often means slower development – the medical sector is usually a few steps behind.

With regard to checking out new materials, the automotive sector is out in front because they have been pushing towards using recycled materials for quite a long time. Having said that, we have seen many engineers and purchasers from the automotive industry move into the medical industry, and some of their behaviours and thought processes are following, but at a slower pace. At Nolato, we are advocates of the mass balance approach, with a mix of bio-based, bio-circular and recycled content, as it offers a drop-in solution that is compliant with regulatory requirements. Chemically recycled materials are clearly coming up as an option for medical applications in the near future, with substantial commercial capacity expected from 2025, while we already use pure bio-based resin for some of our packaging products.

A large part of why the medical sector is so cautious is because of legislation, so we need to have support from the legislators to drive the development. Certainly, in Europe, following the Green Deal, there is a range of different new directives, such as the Design Directive, that now will come into play. The EU is putting a lot of energy into this, and I expect that things will move as a result. And, because most pharma and medical device companies are global, if they move in Europe, they’re likely to move elsewhere as well.

Q Why is sustainability of particular importance to a company such as Nolato?

A Nolato started in 1938, just before the Second World War broke out. At that time, it was not easy to get ahold of materials, so the founders went out to collect old rubber boots that they had previously sold because they couldn’t get enough as raw material. They then used chemical recycling to get the material they needed. In a way, we’re closing that circle now. In the early Eighties, we started with the first Nolato Spirit booklet. That was before we were listed – we were just a small, mid-sized Swedish company. The owners, who still have the majority of the voting power on the company’s board today, take sustainability very seriously.

“We understand that we’re part of a larger picture and part of society and think that sustainability is not only necessary for the planet and for the future – it’s also actually a business opportunity for us.”

We understand that we’re part of a larger picture and part of society and think that sustainability is not only necessary for the planet and for the future – it’s also actually a business opportunity for us. This way of thinking is why we are integrating sustainability in our business model. We want to help guide our customers and support them in making more sustainable products for the future.

Q How are sustainability initiatives organised and structured at Nolato in practical terms?

A It’s a combined model. We are a decentralised company, meaning that we have a small central Group management with some small support functions, with the majority being the individual companies and the managing directors driving those businesses within the various business areas, reporting to the President. A number of years ago, I was appointed as Sustainability and Technical Director, reporting straight to the CEO, with the goal of really integrating sustainability into the Group.

We don’t want to have a specialist – we want to have sustainability really infused in how we do business at a cultural level. What we’re doing centrally is to set the direction and the pace for the Group. For example, this includes initiatives like our climate strategy and signing up to programmes like the Science-Based Targets Initiative, which need to be done at a corporate level. We also have a small team that supports the individual companies.

For the last decade, we’ve been focused on Scope 1 and Scope 2 greenhouse gas emissions, making our factories as energy-efficient and low-emitting as possible, increasingly running on renewable energy. Now, we’ve started focusing on Scope 3 emissions – which comprise 96% of our overall footprint. We have identified that over 70% of that originates from the input material, which makes it really important to operate as a gatekeeper between suppliers and customers, trying to identify what products and applications can be used in line with our sustainability principles, and ensuring that we have these materials available, as well as finding new alternatives on the market.

Q Can you explain how, as a CDMO, Nolato enables its customers to make more sustainable products and follow eco-design principles with their products?

A This is really getting to the core of how to do sustainable development. The most important thing is for us to get in during the early stages of a development project. This is when engineers can ask “How do we apply eco-design principles to this project?” Eco-design is something you can only really do when you start a project. If you are going to just produce something that has already had its design frozen, that really limits your ability to have an impact.

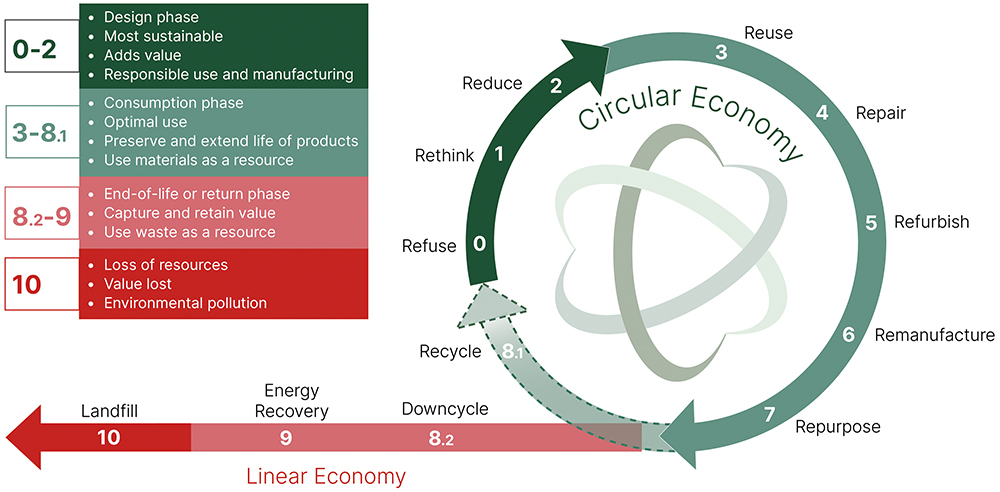

Figure 1: Nolato’s eco-design principles.

Fundamentally, eco-design is quite easy if you peel off all the layers; it’s about making things simpler and easier, understanding that less is more, and, in many cases, applying common sense (Figure 1).One key thing we can do is apply digital tools to simulate parts. I’m not just talking about mould-flow analysis and how we can make a component. The real value comes when you combine those slightly distorted virtual models out of the moulding-phase simulation and then assemble them – still virtually. This lets you understand the functionality of your product to really see where you have the greatest potential for improving that functionality and optimising your carbon footprint.

For example, this approach can show parting lines where you have issues and how the part interacts during the assembly process. Then, using software from our computed tomography scanner, we can set up a measurement study on the virtual model before we even have a physical product. And, by having a conversation with the customer at that stage, live on the computer, we can turn the product around – show that there’s a potential issue here, a possibility to reduce material use there, really get at what improvements are possible.

There can be a bit of engineering negotiation here on where you should set the tolerances so that we can focus on the right areas. This way, we can gain more freedom in the manufacturing process and maybe eliminate some excess material, which is key to creating a good product overall. Of course, we then use some of the other principles as part of the eco-design model, such as selecting materials that aren’t over-specified, making good use of standard polypropylenes or polyethylenes instead of going to high-end polyamides and polycarbonates, because that has a major impact on the CO2 footprint.

We also try to reduce the number of different materials and move more and more towards mono material products, which facilitate better end-of-life processes. And, if it’s a high-value product, we also look at the assembly process, trying to ensure that it’s possible to disassemble it and, potentially, refurbish it (Figure 2).

Figure 2: Nolato’s “R” strategy for transitioning towards a circular economy model based on eco-design principles.

In summary, you could say we enable and support our customers with an array of different software packages and analytical methods, which we then combine with our operational model.

Q Taking a step back and looking at sustainability globally, what’s your take on how things stand – what is going well and what needs to change or improve?

A I think that we certainly need both the carrot and the stick. There will be companies on the forefront of progress that are not afraid to make moves that will potentially cost them some money because most of these alternative, more sustainable materials will currently be at a premium cost. Having said that, there are also options where you can use simpler materials with cost savings and still meet the technical requirements. One example is changing a polycarbonate/acrylonitrile butadiene styrene blend into modified polypropylene for an existing part to reduce CO2.

Looking beyond that, I think there has to be a combination where the legislators become more open to sustainable options, as well as make sustainability requirements a necessity for new products, just as we’re currently seeing take place in the packaging industry. This will also be true of other industries, but pharma puts a heavy emphasis on the risk management side of things, so you have to know what you’re doing when implementing new processes and materials.

However, I think that there has been a lot of confusion surrounding sustainability because there is not a clear definition of certain key words around the subject. What makes it difficult is that some companies have a somewhat relaxed approach to how they use sustainability terminology, especially in marketing. I hope that will change with the EU’s Green Claims Directive. What we need is standardisation of the language and methods we use.

For example, when you calculate your CO2 footprint, we should know that you are doing it the same way the rest of the industry does it. The vocabulary needs to be clear. Part of this is the need to educate and train our own employees, but it is also critical to educate our customers, suppliers and the general public actually about this. Simply put, sustainability is a new broad science area and there is too much confusion surrounding it.

Some industries are already pursuing this. For example, one initiative in the chemical industry is developing a guideline where they agree on how they calculate a product’s lifecycle analysis and how they perform product CO2 footprint calculations. This way, companies across the industry will all be following the same definitions and process. I’ve seen similar steps taken in the automotive industry. It’s really positive when an industry comes together and establishes the rules they are going to collectively operate under.

“There are standards about lifecycle analysis calculations, but they are still too general, too fluffy, for the nitty gritty details of making a polymer.”

Overall, there are standards about lifecycle analysis calculations, but they are still too general, too fluffy, for the nitty gritty details of making a polymer. We need general agreement on everything from energy and water usage to transport, and that agreement needs to translate into clear guidelines for companies to follow. I think that there will be requests from customers – we’ve seen it in some industries already – where, when we provide a quote for a product, they provide a spreadsheet for us to populate with sustainability data, sort of an open book calculation. This lets customers calculate not only the price of the component but also the product’s CO2 footprint as a part of the quotation.

“We need general agreement on everything from energy and water usage to transport, and that agreement needs to translate into clear guidelines for companies to follow.”

Q Finally, how do you see sustainability evolving in the longer term, as it applies in the pharma industry and drug delivery sector in particular – what do you think the future holds?

A If we start from the top, I think there are three pillars – you have environmental responsibility, social responsibility and then you have business conduct, which is primarily about business value. At present, the industry is mainly focused on the environmental aspect, on the climate and CO2. However, while CO2 is a pressing issue that we need to address, water usage is also a major factor that we should be talking about. Some business segments, especially those closer to the electronics industry, typically use a lot of water. We need to keep in mind that there is more to sustainability than just the CO2 footprint – for example, the preservation of biodiversity is starting to receive greater focus.

Legislation will have a key role to play in this. For example, with the EU’s new Corporate Sustainability Reporting Directive, I expect that more focus will be placed on the other factors as well, not just on climate. Another EU directive, the Corporate Sustainability Due Diligence Directive, relates to companies’ responsibility for working conditions and human rights in their supply chains. I think this is part of the social responsibility aspect – brand owners will have to protect their brand by being able to assure their customers that they have their supply chains under control. This introduces new things to consider, like geopolitical risk. If you have certain suppliers in certain countries, you’ll need to have more than a remote questionnaire; you might have to make an on-site audit and have more robust risk-management systems in place.

So, I think sustainability will cover a wider array of principles and not just be singularly focused on climate change, but that it will still be the main topic for the immediate future.

Find out more about Nolato’s sustainable development solutions, here.