To Issue 138

Citation: “Product Showcase: Aktiv Pharma’s ARAI Autoinjector Platform”. ONdrugDelivery, Issue 138 (Oct 2022), pp 44–46.

Figure 1: ARAI – Aktiv’s advanced emergency autoinjector platform. Six ARAI Gen-1 products are currently being advanced to NDA submission.

In 2013, the US Department of Defense (DoD) issued a request for proposals to develop a glass-free autoinjector. In practice, glass-free was just one of a rigorous set of the DoD’s requirements, which also included improved usability, robustness, drug stability and reliability. In essence, what the DoD was after was a next-generation autoinjector that would improve on the shortcomings of the autoinjectors available to them at the time. Importantly, the DoD was looking for a platform that would be amendable to a range of applications and drug formats.

The desire for such a platform approach has been a staple of the autoinjector industry for many years, and the progress made in this direction has filled many pages in past issues of ONdrugDelivery Magazine. In this regard, Aktiv Pharma had one major, counterintuitive advantage – at the time, the company did not have an autoinjector, or any experience of developing one, and was therefore not constrained by established paradigms. Aktiv approached the development as a whiteboard exercise – the company listened and took notes on all the requirements and goals that were presented. It then put its innovation engine to work and built the ARAI autoinjector from scratch.

This small first step led to a long-lasting partnership between Aktiv and the US government. To date, the company has secured over US$70 million (£64 million) in government funding to develop the ARAI platform (Figure 1) and is anticipating the total value of its US government contracts to reach up to $300 million by the end of 2022, which will support the continued advancement of its portfolio of six emergency autoinjector products to commercialisation. This is currently the strongest portfolio of US government-oriented autoinjector products (Table 1), and Aktiv is planning to add several other high-value consumer-market products to its pipeline in the coming years, both independently and in partnership with other pharmaceutical companies.

| Product Name | Configuration |

| Pralidoxime chloride (2-PAM) | Single compartment 2 mL |

| Scopolamine | Single compartment 1.2 mL |

| Tranexamic acid (TXA) | 1,000 mg in 2 mL; 2,000 mg in 4 mL |

| Atropine | Single compartment 0.7 mL |

| Dual-injection atropine/2-PAM | Two single-compartment containers: 0.7 and 2 mL |

| Atropine reconstitution | Single container, dual-compartment |

Table 1: Aktiv’s autoinjector pipeline consists of a variety of configurations, all made using the same basic components and manufacturing lines.

Figure 2: ARCH – the glass-free, flexible primary drug container used in ARAI.

Internal studies have shown that ARAI has superior reliability and robustness, and is simple and intuitive to operate, even for novice users. Its unique features lend itself to the platform approach – ARAI is designed to allow a dose volume range from <1 to 5 mL, an option for injection of separately stored drug constituents through drug-specific needles into separate depots to eliminate adverse interactions between the drugs, and an option for automatic reconstitution of the dose just prior to injection. All these configurations use the same basic device components and share the same manufacturing equipment, with the major change between configurations limited to the size and form of the primary container, which is achieved by a disciplined separation of functions that minimises dependencies between the subsystems of the autoinjector.

Unlike other autoinjectors, the ARAI autoinjector relies on Aktiv’s proprietary glass-free flexible primary container made from high-barrier films, in a form of blister package named ARCH (Figure 2). The ARCH blister package can be made in a range of volumes and can have a single compartment or a plurality of adjacent compartments, which can be merged by peeling a frangible seal separating them, without the need for any moving parts. Aktiv is collaboratively working with the US FDA on the regulatory approach to ARCH via the Emerging Technology Program.

The ARAI autoinjector is activated by a power-pack containing pressurised CO2. Upon activation of the autoinjector, the released gas deploys the needle and, when the needle reaches the target depth, the pressure compresses the ARCH primary container and delivers the dose. After a pre-determined dwell time that ensures complete delivery of the dose, the needle is retracted to a safe and concealed position. There are no mechanical connections between the power-pack and the primary container or the needle-activation mechanism.

“Since there are no mechanical connections between the subsystems, the form factor of the device is not constrained to a pen shape and can be easily changed to other formats, such as a wearable injector.”

The rise in gas pressure in the device drives all device functions, meaning that developing an ARAI product with a new dose volume only requires a new ARCH container and no changes to any other parts. Similarly, since there are no mechanical linkages, the needle gauge, needle length and injection depth are configurable with minimal changes to the device assembly. The injection pressure can also be fine-tuned to accommodate a range of viscosities. The initial pressure of up to 65 bar is adjusted through an arrangement of a valve and bleed holes that operate independently from other functions of the device.

ARAI is not limited to Aktiv’s proprietary ARCH primary container and can also accept regular glass or moulded plastic cartridges, blow-fill-seal cartridges or even plastic or aluminium tubes. A patented approach creates pressure equilibrium between the inside of a rigid primary drug container and its surroundings, eliminating stresses on the container’s walls during injection and preventing damage at elevated pressures. Form factors are also very configurable – since there are no mechanical connections between the subsystems, the form factor of the device is not constrained to a pen shape and can be easily changed to other formats, such as a wearable injector (Table 2).

| Attribute | Options |

| Injection parameters | • Injection time: 0.2 s or longer • Needle dwell time: up to 30 s • Needle gauge: – demonstrated 18–25G – intramuscular or subcutaneous • Back pressure configurable for low and high viscosities |

| Payload | • Volume: <1 mL up to 5 mL • Single-compartment, dual-compartment mixing/reconstitution, dual-container simultaneous injections |

| Primary container | • Glass or plastic cartridge • Any collapsible container: blister, blow-fill-seal, tube, pouch, injection moulded |

| Form factors | • Pen-shaped • Wearable • Others |

Table 2: The ARAI autoinjector architecture supports a wide range of injection parameters, payloads, primary containers and form factors.

This strict separation of functions also lends itself to the superior reliability of ARAI. Aktiv has recently demonstrated that ARAI exceeds the 99.999% successful activation rate required by the recent FDA draft guidance. During the development of the ARAI autoinjector, particular attention was paid to defining critical functions in a manner that allows the platform’s advantages to be fully realised. This was done by producing reliability specifications for each function, which then allows for new devices to be developed with confidence that they will also meet the overall reliability requirements.

Even the feedback of the user interface was designed not to alter device reliability. Unlike other autoinjectors, where audible or other feedback cues require additional subsystems that can potentially reduce reliability, ARAI’s tactile, audible and visual feedback is generated by the critical device functions. This kind of platform flexibility and reliability is nearly impossible to achieve with spring-based autoinjectors, which are burdened by high sensitivity to dimensional tolerances and subsystem interdependencies.

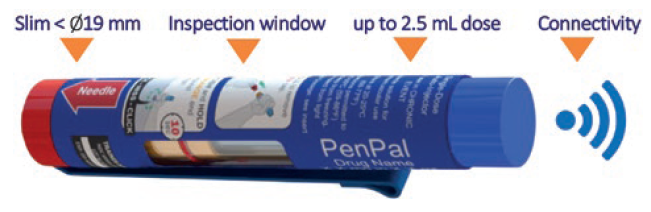

Figure 3: Aktiv’s PenPal platform, currently under development, combines the advantages of ARAI with essential features for consumer applications.

In addition to ARAI, Aktiv is developing PenPal (Figure 3), a connectivity-enabled autoinjector for the consumer market that embodies all the advantages of ARAI in form factors that are more suitable for chronic conditions. Aktiv is also partnering with a leading biopharmaceutical company to develop a glass-free container closure system for biologics that eliminates drug contact with problematic materials associated with glass, such as silicone and rubber, improves usability and logistics and reduces drug wastage and environmental impact.