Citation: Merhige J, “Technology Showcase: Credence MedSystems Multi-Site™ Injection System”. ONdrugDelivery Magazine, Issue 97 (May 2019), pp 26-27.

While Credence MedSystems has become known for its Companion® Safety Syringe System and Dual Chamber Reconstitution products, another focus area for the company is the development of products to support specific therapeutic applications. As a result of this approach, Credence is now introducing the Multi-Site™ Injection System – a product that addresses specific needs in the high-growth dermal filler market, which is expected to exceed US$8.5 billion (£6.5 billion) by 2024.1

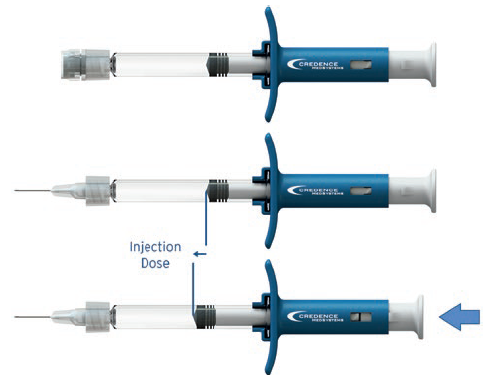

Figure 1: The Credence Multi-Site™ Injection System.

Administration of cosmetic injections such as dermal fillers and cosmetic botulinum toxin is performed by healthcare professionals (HCPs) in an office/clinic setting. During this procedure, the HCP administers several small-volume injections, often of a highly viscous substance through a fine-gauge needle, into multiple sites on the recipient’s face or other areas of the body. Some of these cosmetic injectable products are delivered to the market in a vial and must be drawn up into a commodity syringe at the time of injection, while others are already in a prefilled syringe (PFS).

This latter PFS presentation has benefits such as simplified user steps, diminished risk for error or contamination, reduced waste from overfill and improved product/procedure traceability. In either presentation, the HCP must endeavour to inject precise doses using only the dose-line markings on the syringe as guidance. The conventional attempt to facilitate this is to use syringes with a reasonable distance/volume between dose lines, such as narrow Tuberculin syringes in the vial presentation or narrow PFS customised for the application.

Neither solution is ideal for the manufacturer or the user. The preferred solution is to use a standard PFS, such as a 1 mL “long” configuration, but the larger diameter makes metering the injection very challenging since the distance between the dose lines is too short. A system is needed that can preserve the benefits and efficiencies of a standard PFS configuration while enabling the procedure to be performed safely, accurately, quickly and effectively.

Figure 2: The Multi-Site System enables precise dosing into multiple injection sites.

Credence is addressing this need with the Multi-Site™ Injection System (Figure 1), which enables the user to deliver a precise dose into multiple injection sites without fear of over- or underdosing. Each time the user presses on the plunger rod to perform an injection, the plunger rod advances until it reaches a firm stopping point that corresponds to the desired injection dose.

The HCP simply presses on the plunger rod until it stops, providing a clear cue that the precise dose has been delivered. This is especially useful on the first injection, where overcoming the break-loose stiction can require an elevated force and a resulting momentum that can cause the HCP to overdose unintentionally.

When the plunger rod is released after each dose is delivered, it resets by retracting to its original position. Each reset is met with a tactile cue that indicates to the user that the syringe is ready for the subsequent injection. To avoid disturbing the patient, that cue occurs when the plunger rod is reset, after the HCP has removed the needle from the site. The process is repeated until the syringe has been fully dosed (Figure 2). The Multi-Site System has been designed to be simple and intuitive for the user but also practical for implementation by the manufacturer. The Multi-Site components are mounted to the back end of an alreadyfilled syringe, allowing the system to be used with any glass or polymer PFS and any closure components. As a result, the filling process is entirely unaffected. Only two items need to be assembled; the finger flange and plunger rod are mounted in secondary packaging and are compatible with existing processes and machinery. The system therefore enables the use of standard PFS but is also applicable to custom barrels.

Understanding that different applications have unique requirements, and that pharma manufacturers have different preferences and priorities, the Multi-Site System allows for significant flexibility on multiple fronts. The per-injection dose volume and number of doses per syringe can be adjusted.

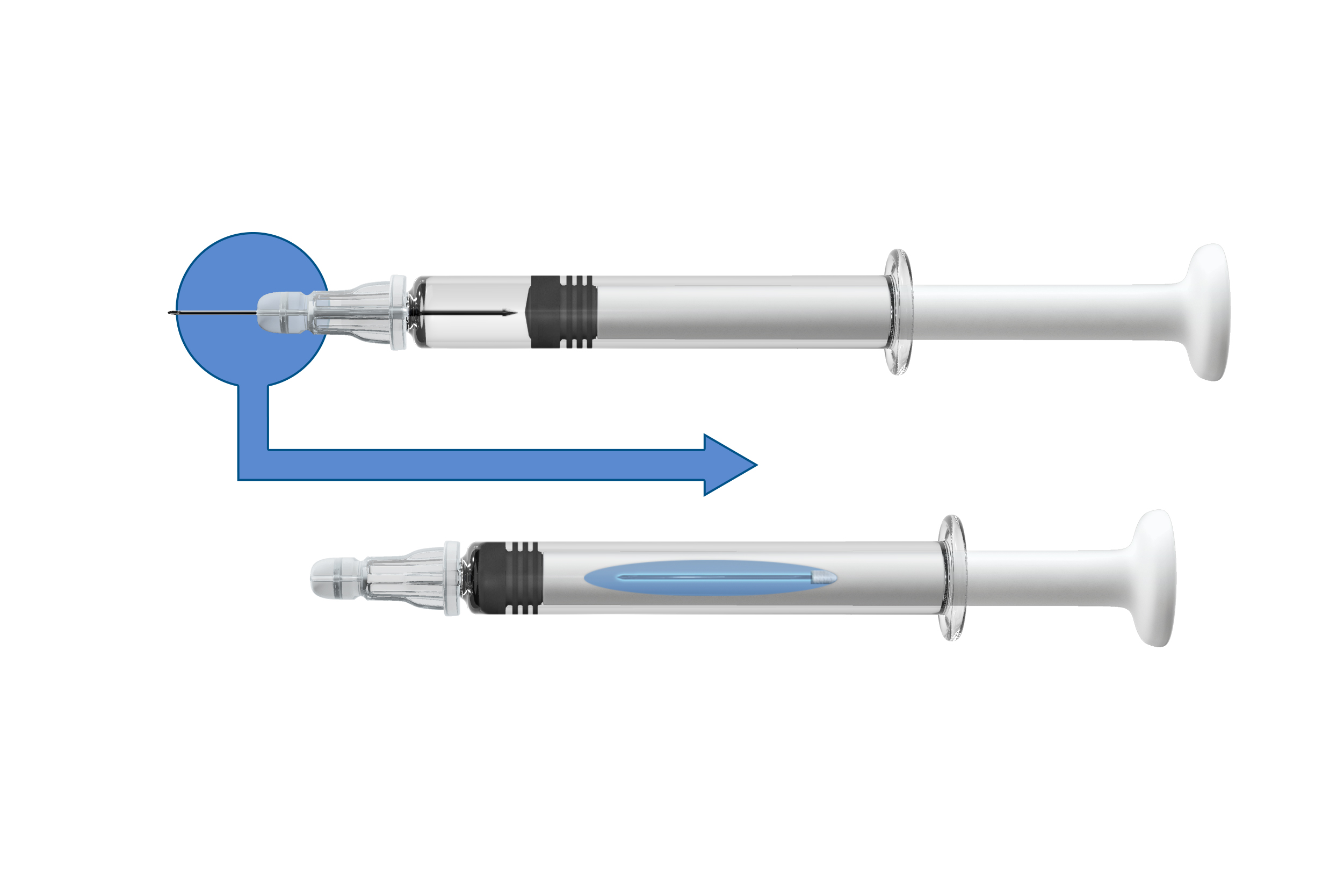

Figure 3: Credence’s proprietary Needle-Retraction Technology is an optional feature.

Multiple branding opportunities exist and the grip and shape of the finger flange can be specified by the manufacturer. The system can be used with standard user-attached needles that exist in the market today – but Credence’s proprietary needleretraction technology can be implemented as an option (Figure 3). In this case, the needle retracts into the plunger rod at the end of the procedure after the final dose has been delivered. This option is available in either a user-attached or pre-attached needle. While the inclusion of needlestick prevention features is not prevalent in this market today, incorporating Credence’s needle-retraction technology provides an opportunity as this would render these procedures compliant with needlestick prevention laws.

Figure 4: Force-Assist makes administration of viscous substances through fine-gauge needles easier.

Finally, pharma manufacturers can choose to include an additional feature called Force-Assist™ (Figure 4), which provides a mechanical advantage to the user. This feature reduces the force required to inject the filler to only one-third of that which would otherwise be required. Because these fillers are generally very viscous – and because fine-gauge needles are used to avoid pain when injecting into the face – the force required to inject can be high. Force-Assist directly addresses this challenge. Credence is focused on listening to customers, interpreting their needs and inventing solutions that address them.

In this case, the result is the Multi-Site Injection System, specifically designed to address unmet needs in the cosmetic dermal filler market, with the potential to simplify and de-risk administration, increase procedure speed and provide enhanced safety and usability.

REFERENCE

1. “Dermal Filler Market Size By Type 2018-2024”. Global Market Insights, December 2018.