To Issue 142

Citation: Block S, Jelgerhuis D, “A Tale of Two Springs”. ONdrugDelivery, Issue 142 (Feb 2023), pp 118–120.

Sebastian Block and Drew Jelgerhuis introduce two types of springs and highlight their important role in drug delivery devices.

“The spring is often used for a triggering mechanism or as a drive spring to push as a plunger dispensing medication.”

With apologies to Charles Dickens and all literary lovers, Scherdel Medtec has stolen from the title of his best-selling novel. There are many lessons to learn from that classic story (A Tale of Two Cities), but one of the main moral lessons is that “things are not always as they seem”. To stretch that lesson to springs may be deemed a road too far, but let’s try anyway.

Springs are rarely seen and often underestimated for their value. They seem easy to make and unimportant. In reality, they serve a very important role in drug delivery devices. So, the lesson is: springs are not always recognised for their value. They seem insignificant but are actually a very key component. This article focuses on two very important spring types: the constant force spring and the power spring – a tale of two springs!

Despite its unimposing form, the constant force spring has an important function. The spring is often used for a triggering mechanism or as a drive spring to push a plunger dispensing medication. The main feature of a constant force spring is to produce high and constant rotational force in a small space (Figure 1).

Figure 1: Constant force and power springs.

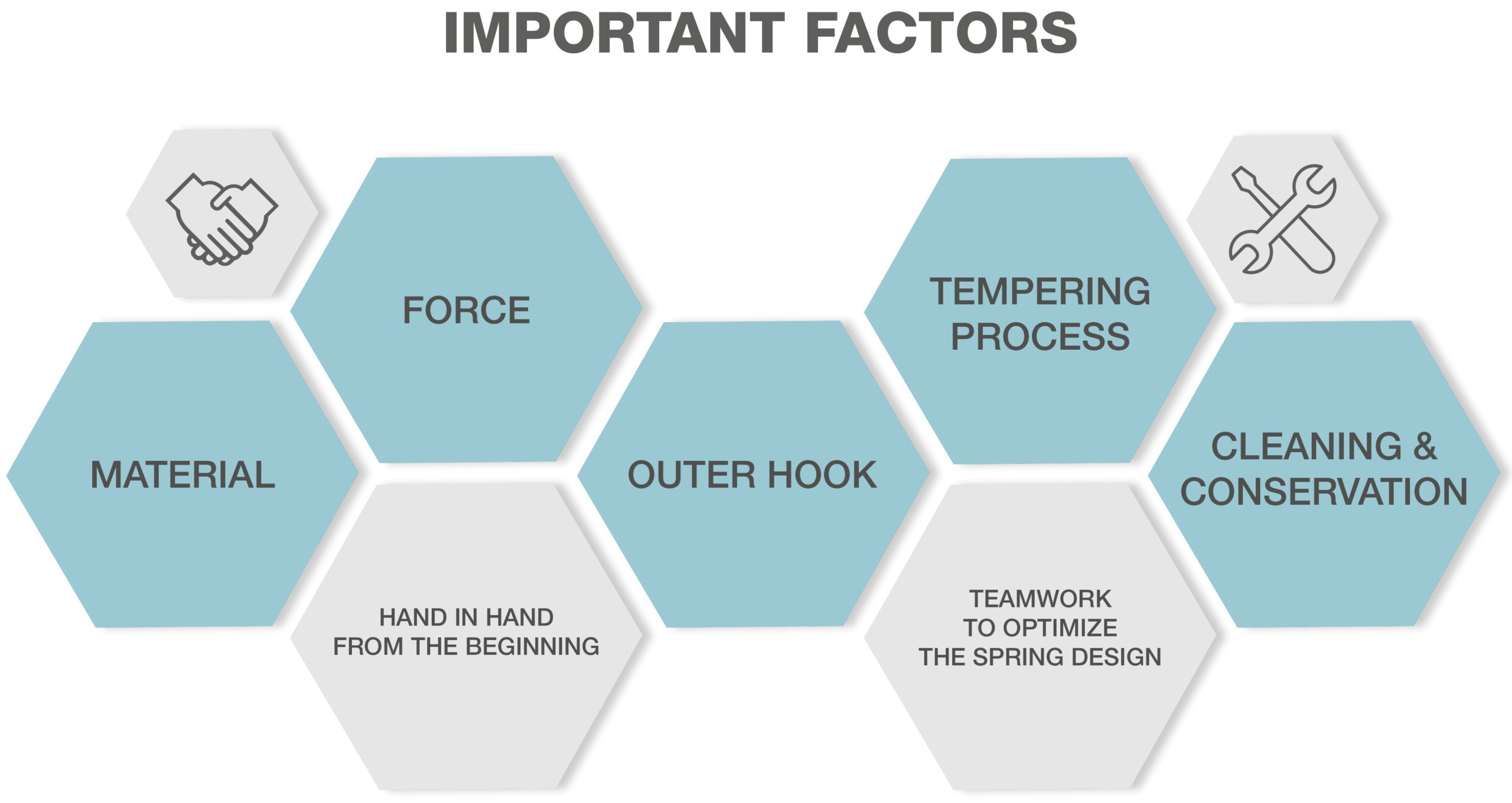

There are many options for the production processes and multiple choices of suitable material. These need to be defined early in the development phase. Scherdel’s development team works closely with the customer’s device development team to optimise the spring design.

“The material width and especially the thickness and tensile strength have a big impact on the force.”

The first design step is to choose a suitable material according to the customer’s needs and requirements. Most commonly austenitic stainless steel AISI 301 or EN 10088-3 X10CrNi18-8 (1.4310) with a high tensile strength (almost 2000 N/mm²) is used for a constant force spring.

Scherdel agrees a special supply contract with the material supplier including the material composition, the state of microstructure and the surface characteristics of the material. Additionally, the geometric characteristics, such as thickness and width, the mechanical and technological characteristics, such as tensile strength, yield strength or modulus of elasticity, as well as the medical requirements (for example, to avoid contamination) are defined.

The production of material includes processes such as milling, heat treatment up to 1,200°C (2,200°F), levelling and slitting, and edge conditioning. The milling process, consisting of several loops, is necessary to achieve the desired thickness and tensile strength. This process is especially expansive (material will be rolled with the 20-roll rolling mill machine) and alternates with the heat treatment process. Subsequently, the material is available with the right thickness on a wide range of coils. The slitting process creates strip widths to match customer specifications. The material supplier coils the strips after edge conditioning. The coiled material from the supplier with the specified thickness and width is unwound from the coiler and formed on the winding machine.

“In contrast to the constant force spring, the power spring has two hooks – one inside and one outside.”

The material width and especially the thickness and tensile strength have a big impact on the force. (For example, for a constant force spring and thickness with a diameter and width of 20 mm: thickness 0.1 mm, force approximately 1.4 N; thickness 0.2 mm, force approximately 11.2 N.) The force can also be adjusted with the spring diameter on the winding machine. That is also very important to compensate for the tolerances of the material characteristics. Additionally, the shape of the outer hook has a big influence on the behaviour of the characteristic line and can also be adjusted on the machine. Special stamping and cutting tools on the machine are necessary and available in Scherdel’s tool shop.

The tempering process is a follow-up process to improve the stress and reduce the stress peaks. The right choice of temperature and time have a significant influence on the forming of the chromium oxide layer for the stainless steel and are also very important as a corrosion protection layer.

For cleaning and conservation, there are also many options, including injection flood washing, ultrasonic cleaning, a vacuum drying process and conservation in Scherdel’s washing machine. Scherdel can also use a cleanroom. The choice of the preservative must be agreed with the customer. For medical technology projects, Universal Oil for Food Processing Technology is often used (Figure 2).

Figure 2: Critical characteristics and Scherdel Medtec advantages.

Across all production processes for the constant force spring – such as forming, heat treatment, cleaning and conservation – the diameter of the spring body, the behaviour within the working range and the spring force can change; the smaller the spring body diameter, the larger the force.

In contrast to the constant force spring, the power spring has two hooks – one inside and one outside. Very often, there is a housing with support for the outer hook and a shaft for the inner hook. In the same procedure used for the constant force spring, the material characteristics are defined by the material supplier.

There is a distinction between three types of power springs. At Scherdel, the types are known as normal, straight material and a cross-curved power spring.

The cross-curved power spring is produced in the first step in the same way as a constant force spring. This spring has the greatest power potential.

The constant force spring with two hooks is wound in the opposite direction, ideally in the customer’s assembly housing. This is the best delivery form for the power spring.

In the development phase, the constant force spring diameter and the shaft diameter are determined to achieve the force or torque and geometrical characteristics. The geometry of the outer hook can have a significantly positive influence in achieving the right power and optimal behaviour of the characteristic line within the working range. Thus, this power spring plays a significant role in achieving a higher constant force for highly viscous drugs in medical devices.

Scherdel has much expertise in the development and manufacturing of constant force and power springs, and the company has a global reach with its engineering and production processes. This tale of two springs reveals the importance and value of these spring types in drug delivery devices and how material, thickness, width, heat treating, milling, hook design and integration into the device are all so important yet often undervalued. Scherdel can optimise the value of these important components by working with the customer’s development team from the initial device concept.