To Issue 165

Citation: Pircher D, “Creating Value – Sustainable Approaches for the Medical Device Industry”. ONdrugDelivery, Issue 165 (Sep/Oct 2024), pp 32–35.

David Pircher provides insights from a sustainability journey, showcasing what suppliers can contribute and how innovation and partnership support a common vision. The article outlines where the industry stands and why sustainability is a top priority, with concrete examples. Future perspectives are explored to consider how progress can be made together through stakeholder involvement and innovative approaches.

In the last decade, sustainability has emerged as a pivotal issue across various industries, including the medical device sector. Traditionally, the medical device industry has primarily focused on advancing technology and improving patient outcomes. However, with growing global awareness of environmental impact and the need for resource conservation, there has been a notable shift in how sustainability is perceived within this industry.

“Over the past few years, the focus on reducing the impact of climate change has increased across the medical and pharmaceutical industries.”

Over the past few years, the focus on reducing the impact of climate change has increased across the medical and pharmaceutical industries.1 As a supplier to this industry, BAUMANN is affected by this issue in exactly the same way as others and is keenly aware of how well the company can contribute to the overall effort to make the world a better place.

Figure 1: Three pillars of the BAUMANN sustainability strategy.

WHY IS SUSTAINABILITY SO IMPORTANT?

BAUMANN addresses sustainability not just as a trend or to meet customer demands but to embed sustainability in the company’s DNA, and has therefore made it a strategic pillar. The company says it can contribute to a better and more sustainable future. In so doing, it has anchored a classic environmental, social and governance (ESG) approach within the company (Figure 1). BAUMANN is driven by an aspiration to become a key partner in the circular economy for medical devices, transitioning from sustainable practices to fully circular solutions.2 The company’s focus encompasses key ESG topics, guided by the pillars of sustainability – safeguarding the planet’s integrity and enhancing quality of life.

BAUMANN considers and understands the economy, ecology and social affairs not as contrary but as complementary systems. Therefore, it is less a question of how the greatest possible profit can be achieved with the least possible damage to humanity and the environment, but more about which business model can achieve a positive impact in all three systems.

WHERE DOES BAUMANN STAND TODAY?

“Sustainability is a journey, and the first step is to align the company, customers and suppliers.”

Sustainability is a journey, and the first step is to align the company, customers and suppliers. Strategic anchoring is key to success. In this process, BAUMANN engaged with its stakeholders to define the vision, goals and measures together. In the first phase, evaluating key data was essential, involving external partners and specialists. EcoVadis, a leading provider of business sustainability ratings, intelligence and collaborative performance improvement tools for global supply chains, was invaluable during this initial evaluation. Thanks to a transparent process and clear outcomes, significant measures have already been initiated and realised. BAUMANN can now also share certificates with its customers directly via a global and transparent database.

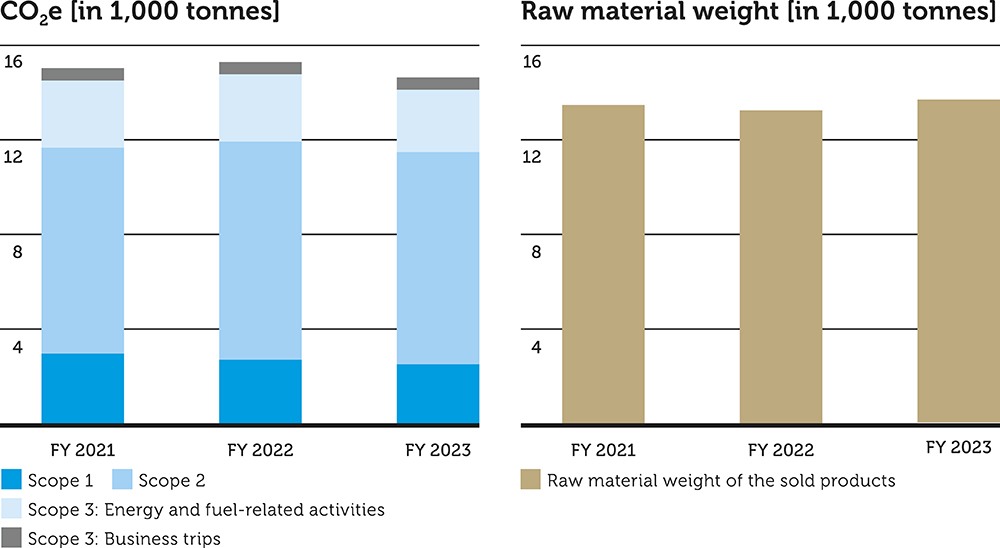

A further step involved collecting even more concrete data to accurately record BAUMANN’s carbon footprint. In the financial year 2023, efforts were focused on introducing the process for measuring the carbon dioxide equivalent (CO2e) emissions for all factories. Following a pilot and training phase between June and August, the process for calculating the CO2e footprint was rolled out in all factories. This step is crucial for defining influential measures that can be placed and implemented on the company’s roadmap. Figure 2 illustrates the development of absolute CO2e emissions from 2021 to 2023 for BAUMANN. From an overall perspective, Scope 3 plays the largest role in CO2 distribution. Even if BAUMANN has only partially covered Scope 3, it is already known that raw materials for metal products leave a large footprint; around 60% of Scope 3 comes from raw materials.

Figure 2: Absolute CO2e emissions measured in the 2023 financial year, compared with the raw material weight of the associated products.

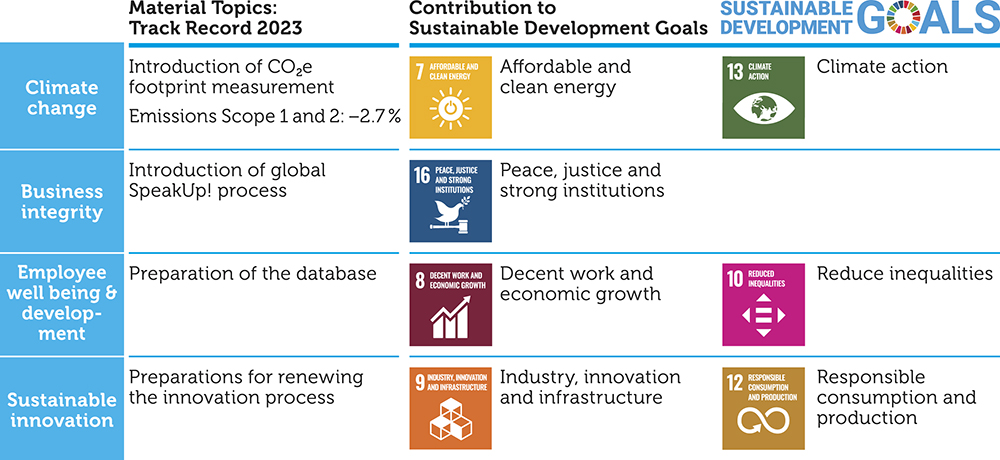

It was important to BAUMANN to use standardised frameworks for measures and target tracking and to align activities with recognised frameworks (Figure 3). That is why the UN Sustainable Development Goals guide the company’s efforts towards achieving a commonly used framework. This approach not only helps BAUMANN to speak a common language but also enables it to achieve its goals more efficiently.3

Figure 3: Focus topics aligned with sustainable development goals.

Figure 4: The photovoltaic equipment on the roof of BAUMANN’s medical plant in Singapore.

CONCRETE EFFORTS

When BAUMANN discusses concrete measures resulting from assessments, the focus is on those that also create value for customers and other stakeholders.

Increasing energy efficiency and the use of renewable electricity to reduce the company’s overall carbon footprint are a top priority. BAUMANN is pursuing a two-pronged strategy: switching to renewable energy when purchasing electricity and, wherever possible, generating its own clean energy.

“Increasing energy efficiency and the use of renewable electricity to reduce the carbon footprint are a top priority.”

- In Singapore, solar energy production began in 2023, covering between 16% and 27% of BAUMANN Singapore’s total electricity consumption with solar panels. The average monthly reduction is 18.7 t/CO2e, which the company considers to be a substantial improvement (Figure 4).

- In Switzerland, renewable electricity has already been included in the basic electricity mix. However, this is not yet sufficient, and an additional 20% was targeted for replacement with renewable electricity in 2023. The goal is to continue increasing this quota step by step.

In 2022, BAUMANN defined measures to reduce electricity consumption through a broad-based campaign and by involving employees. This resulted in a variety of inputs, including upgrading the lighting to the latest LED technology, increasing the use of motion detectors for lighting, optimising the heating oven management system, and designing general switch-on and switch-off cycles for machinery.

For the management of hazardous substances in the environment, health and safety area, BAUMANN has clear plans and is well-positioned in hazardous substance management. This is not only for the protection of employees but also to ensure risk-free use for further processing and for consumers of the products. For more than a decade, no incidents have occurred involving dangerous substances.

ACCELERATING SUSTAINABILITY

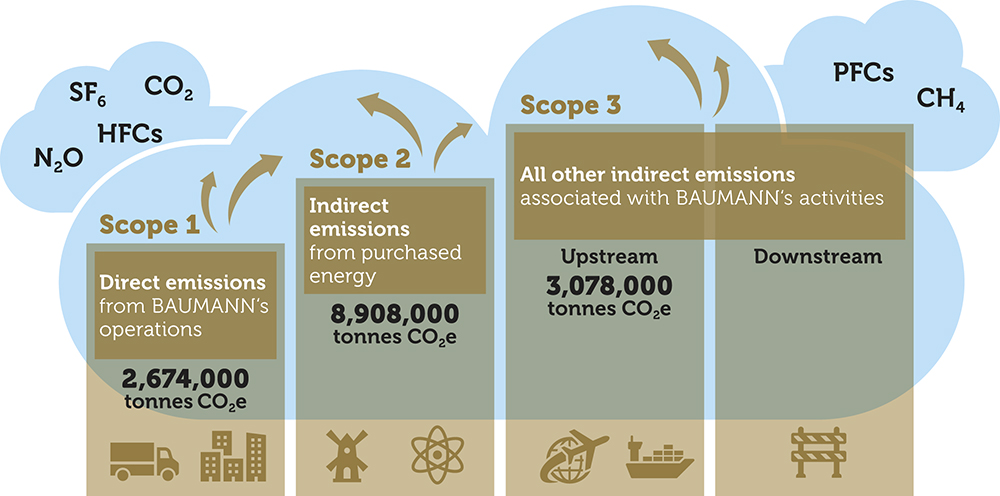

BAUMANN has identified clear next steps to achieve significant progress in sustainability (Figure 5). As a top priority, the company has set the goal of significantly reducing negative environmental impact and climate effects caused by its business activities. The achievement of these goals is measured by two key performance indicators (KPIs):

- Increasing the percentage of green electricity from 20% (2022) to 40% (2026)

- Reducing the consumption of natural gas by 20% by 2030 relative to 2022.

Figure 5: A graphical representation of BAUMANN’s current absolute emission values.

These two KPIs were chosen because they are primary drivers of BAUMANN’s CO2e footprint (electricity and natural gas consumption). Together with other local actions aimed at reducing emissions, BAUMANN aims to reduce emissions in Scope 1 and 2 by 10% (relative to the weight of produced articles) by 2026. For example, improving energy efficiency through insulation and optimised heating and cooling strategies at the company’s headquarters.

Since 80% of BAUMANN’s gas consumption in Switzerland, which has a total impact of around 900,000 tonnes CO2e per year, is currently used for heating, the reduction in natural gas consumption can be drastic. If it is not feasible to construct new buildings, maintaining older buildings becomes crucial. The leverage BAUMANN is seeking, for instance, by renovating the building envelope of its headquarters, which is over 100 years old, is substantial and will reduce the total heating demand by approximately 60–80%.

Developing a more far-reaching strategy for employee wellbeing is not always just about measures in the environmental area, even though these often have the greatest visibility and provide significant benefits to customers. For example, to ensure optimal performance and superior products, the company focuses on the wellbeing of its employees. By fostering a positive culture and retaining its experts over the long term, BAUMANN secures the development and retention of valuable knowledge. This, in turn, enables the company to assist customers in reducing assembly line rejects through consistent quality and continuous product optimisation, ultimately enhancing overall cost efficiency.

“By determining the CO2 footprint early in the design phase, BAUMANN can collaborate with customers to revise designs and cut emissions.”

Over the next few months, BAUMANN will enhance its systems to provide customers with precise product CO2 footprints. This will facilitate discussions on optimising products and processes, reducing both CO2 emissions and costs. By determining the CO2 footprint early in the design phase, BAUMANN can collaborate with customers to revise designs and cut emissions. For instance, reducing the number of coils in a compression spring for an autoinjector from 20 to 18 could lower its carbon footprint by nearly 20%, without impacting assembly line performance.

INTERACTION WITH STAKEHOLDERS

At BAUMANN, the emphasis is on partnerships to achieve sustainable goals. Addressing circular economy issues requires collaboration with all stakeholders to enhance the entire value chain.

The company aims to develop solutions with its customers, focusing only on concrete projects that make sense. BAUMANN has already received specific requests and is actively seeking dialogue, engaging in joint projects and setting shared goals. While reports and certifications are important, collaborations must go beyond these formalities. The outcomes of shared sustainability approaches are:

- Change from small bag packing to reusable box packing. This initiative was created together with the company’s contract manufacturer and packing supplier. Generically calculated, it is possible to reduce emission impact by over 80% by switching packing solutions.4

- Collaborating with R&D and equipment suppliers, BAUMANN is testing energy-efficient heating technologies, such as resistive heating, which could save around 30% of energy compared with conventional batch ovens for compression springs. This will also reduce the product’s CO2 footprint, with further tests planned in production environments.

CONCLUSION

In most cases, measures to optimise sustainability benefit not only the company but also its customers and suppliers. However, sustainability is a journey – a journey that requires time, knowledge and experience, which BAUMANN would like to pursue together with its stakeholders. One aspect is particularly important: to address the issue sustainably, there must be collaboration within the industry and the sharing of common visions.

Collaboration is key to maximising value in sustainability. By working together early in the development of medical devices, components that are reusable can be designed without compromising patient safety or health. Involving BAUMANN early ensures optimal outcomes in achieving these goals. As sustainability and circularity2 are fuelling innovation in the industry, transforming the entire product design will help to create value propositions.5 All companies ultimately supplying the pharmaceutical value chain encounter significant challenges and bear the crucial responsibility of reducing their carbon footprints. BAUMANN is more than ready to start discussions and joint developments to change the future now. Further information can also be found in the company’s sustainability report.

REFERENCES

- “The CPHI Sustainability Report 2023: Towards a Greener Future”. CPHI, May 2024.

- “Transforming the Medical Device Industry: Road Map to a Circular Economy”. Health Affairs, Dec 2020.

- “Sustainability report 2023”. BAUMANN Federn AG, Mar 2024.

- “The Potential Impact of Reusable Packaging”. McKinsey & Company, May 15, 2024.

- Marquet M, Vetters R, “Driving Innovation in MedTech: The Power of Circularity and Sustainable Product Design”. EY, Jun 2024.

Previous article

FROM VISION TO VICTORY: BUILDING A HANDS-ON ESG FRAMEWORKNext article

INTERVIEW with GLENN SVEDBERG