Citation: Dean C, Sinclair K, Miles B, “Eight Essential Sustainability Terms for the Medical Device Industry”. ONdrugDelivery, Issue 126 (Oct/Nov 2021), pp 25–29.

Kay Sinclair, Brennan Miles and Charlie Dean provide an overview of eight terms key to a common understanding in the ongoing, and crucial, discussion surrounding sustainability.

“When thinking about sustainability, many companies focus on the pressing issue of climate change. However, it is important to maintain a full understanding of the term to allow for a more holistic and strategic approach to problem solving and mitigation efforts.”

In recent years the subject of sustainability has transcended from the discussions of the scientific and political world and permeated into our professional lives and even household conversation. This has been keenly felt in the medical device industry, where the criticality and emergency of sustainability is fast becoming a key focus. For most pharmaceutical professionals and medical device developers looking to do their part, understanding the deeper scientific and socioeconomic factors involved in sustainability may be prohibitively laborious. However, it is still important for all companies to work with a common understanding of the issue and the terms involved. This article presents a brief list of sustainability terms and how they apply to medical device development that would be beneficial for our industry to know.

1: SUSTAINABILITY

Definition

The simple definition is “the ability to maintain something on its current path or development”, but Sustainability (with a capital “S”) points to the modern definition widely accepted in the UN’s Sustainable Development Goals (SDGs).1 The 17 goals highlight the breadth of this term, covering not just the climate, but all manner of emergencies that threaten humanity’s healthy, peaceful and prosperous existence on planet Earth – from poverty to education and more. If you’re after a gold standard definition of sustainability, this is it.

How This Applies to the Industry

When thinking about sustainability, many companies focus on the pressing issue of climate change. However, it is important to maintain a full understanding of the term to allow for a more holistic and strategic approach to problem solving and mitigation efforts. This will help to reduce the chance of exacerbating one issue while rushing to solve another, or even allow companies to solve multiple problems with one well-placed policy. For example, creating manufacturing sites in multiple locations around the world can reduce the carbon footprint of a vast transportation network, while also creating jobs and boosting the economy in lower-to-middle-income regions.

Many companies incorporating sustainability into their business approach choose to follow the principle of the “Triple Bottom Line” (TBL) – a term elevating social and environmental factors to stand alongside economic factors. The TBL was, and still is, a powerful concept to enact positive change. However, it is not sufficient on its own to capture the fullness of the challenges we face. Instead, it is prudent to rely on the UN SDGs for a more comprehensive definition of sustainability.

2: GREENHOUSE GAS EMISSIONS AND CARBON FOOTPRINT

Definition

Greenhouse gas (GHG) emissions and carbon footprint are interchangeable terms relating to the total emissions caused by human activity. This could be the manufacturing of a product, driving a car or emissions from an individual’s lifestyle. Methane from domesticated cattle also counts here, as rearing livestock is a human activity. While GHG emissions (or carbon footprint) is an expression of the total amount of GHG emissions, the values are typically normalised and expressed in terms of carbon dioxide equivalent, typically as grams or kilograms of CO2-eq.

How This Applies to the Industry

There are numerous gases and gas sources that contribute to the greenhouse effect. Understanding them is key to mitigating them. The most well-known example of GHG emission is the burning of fossil fuels, which releases carbon dioxide into the air. This occurs in transportation, heating and several forms of energy generation, such as coal-fired power plants.

Manufacturing processes that require electricity therefore contribute GHGs by association, owing to the method used to generate the energy required. For example, energy intensive processes in medical device development, such as printed circuit board manufacture, have high carbon footprints. This has caused the recent trend among some organisations to bolster their on-site renewable energy in order to reduce their reliance on coal-fired energy grids.

Some gases are also emitted due to the inherent chemical or physical process involved in the healthcare industry’s regular activities. For example, pressurised metered dose inhalers (pMDIs) use pressurised fluorinated gases to aerosolise a drug formulation for inhalation. These gases, such as hydrofluoroalkanes (HFAs), have especially high global warming potential. As such, the continued use of these gases in pMDIs is under heavy debate.

“Manufacturing processes that require electricity therefore contribute GHGs by association, owing to the method used to generate the energy required.”

3: NET-ZERO CARBON TARGETS

Definition This is a goal that a person, organisation or government sets themselves whereby they pledge to reach net-zero GHG emissions by a specified date. The term “net-zero”, not “zero”, is key here, as it is impossible to mitigate all emissions entirely. With every best effort there will always be legacy or residual emissions. To hit these targets, there is a need to remove emissions from the atmosphere by at least an amount equivalent to that emitted.2

Compared with the similar term “carbon neutrality”, a key aspect of achieving net-zero carbon targets is that reducing emissions is the first priority, with carbon offsetting only being used to balance the remaining emissions. In contrast, carbon neutrality often refers to simply purchasing carbon reduction credits in order to proceed as normal, with no transformation to any proprietary operations.

How This Applies to the Industry

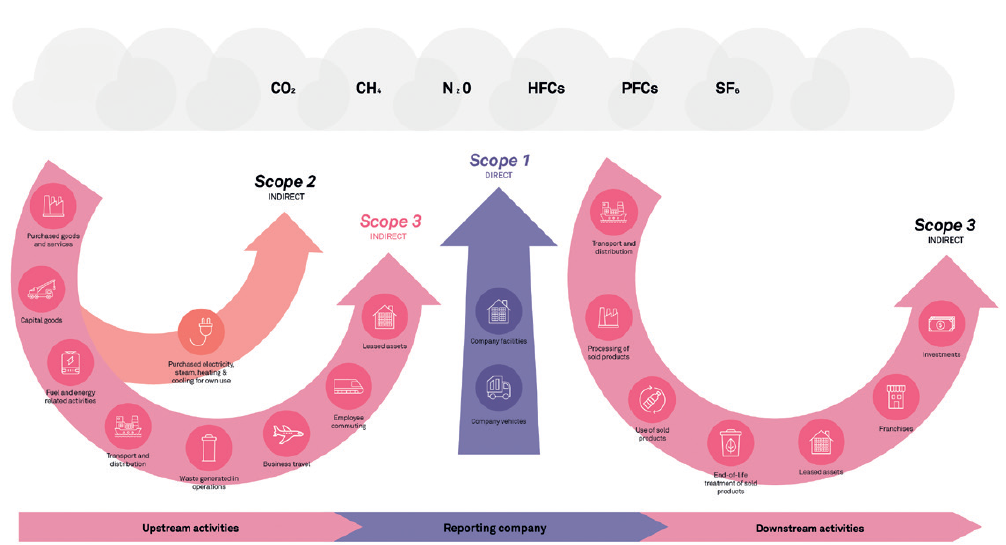

With governments beginning to pass laws aimed at ending global warming, it is fast becoming relevant for organisations to set their own targets to reduce emissions. What this means for each organisation will differ, making measuring emissions a key activity. The GHG Protocol is the most widely used accounting framework for quantifying and measuring these emissions (Figure 1).3 The protocol breaks down emissions into three categories:

- Emissions directly caused by an organisation’s activities

- Indirect emissions from purchased electricity or other energy sources

- All other indirect emissions from activities within the value chain.

Figure 1: Overview of GHG Protocol scopes and emissions across the value chain.

“As global warming is one of the key facets of the climate emergency, GHG emission is typically the impact category of most interest. However, there is great value in being aware of the other categories so as to not create more problems by rushing to solve only the most obvious one.”

4: CARBON OFFSETTING

Definition

The act of carbon offsetting involves removing GHGs from the atmosphere to balance against an organisation’s residual GHG emissions. As mentioned prior, it is impossible to remove emissions from one’s own operations entirely.

There is heavy debate between the two methods of carbon offsetting schemes:

- Reduction schemes: These reduce (non-proprietary) emissions through renewable energy projects, such as wind farms or solar panel projects. Purchasing credits in reduction schemes results in reducing future emissions elsewhere but does not remove emissions to balance against an organisation’s own residual emissions.

- Removal projects: These absorb GHGs from the atmosphere, most notably through planting trees or “sequestration”.

How This Applies to the Industry

With numerous opportunities for absorbing emissions from the atmosphere, it can be challenging for businesses to determine which project most closely aligns with their organisational goals and core values. While it may seem like a monumental challenge, the best approach is to start small and build from there. Aiming for a running start of measuring your emissions and removing all residual emissions may be overwhelming, which is why organisations set net-zero targets for the future and build roadmaps to achieving their goals.

Figure 2: Ellen MacArthur Foundation – Circular Economy.

5: CIRCULAR ECONOMY

Definition

Developed by the Ellen MacArthur Foundation, the “circular economy” is a novel methodology for driving system change for a more sustainable economy. Instead of the linear cradle-to-grave or “take-make-waste” industrial model, the circular economy aims to redefine industry with a “cradle-to-cradle” approach (Figure 2).4

How This Applies to the Industry

Applicable to numerous industries, this system aims to address a number of environmental issues, primarily surrounding the depletion of natural resources and excessive generation of waste. It encourages going back to the drawing board and rethinking product lifecycles to embed recycling, repair, re-use, refurbishing, maintenance and other approaches with the aim of making more efficient use of resources and energy, as well as minimising waste and pollution.

The circular economy shifts the focus from purely a product design-oriented solution to the climate emergency, to more of a service design-oriented one. A sustainable design is unlikely to be achieved through product design alone.

6: LIFECYCLE ASSESSMENT

Definition

Lifecycle assessment (LCA) is a widely recognised (ISO 14040:2006) environmental management framework for assessing the environmental impacts of a product or service. Often misinterpreted as being a tool only for analysing a product’s carbon footprint, LCA is more appropriately used for a wide range of impact categories, with GHG emissions being only one of many. Other uses for LCA include assessing:

- Land use

- Water use

- Resource efficiency

- Hazardous and toxic material waste

- Heavy metal content (HMC).

As dictated in ISO 14040, the principles of LCA involve four key stages:

- Goal and scope definition

- Inventory analysis

- Assessment

- Interpretation.

During the goal and scope definition stage, it is critical to be clear which impact categories are of most relevance, usually determined by where the impacts are regarded as being highest, or perhaps where there is most opportunity for mitigation. As global warming is one of the key facets of the climate emergency, GHG emission is typically the impact category of most interest. However, there is great value inbeing aware of the other categories so as to not create more problems by rushing to solve only the most obvious one.

How This Applies to the Industry

Minimising a medical device’s environmental impact is a complex, multi-variable and highly technical challenge. LCA is a widely used and methodical way of managing this process by providing quantitative insights into device or drug development to drive environmentally friendly choices.

7: BIOPLASTICS

Definition

Bioplastics are polymeric materials derived from biomass sources. These biomass sources are typically renewable sources that can either be waste from food and agricultural processes, or derived from sources specifically used for polymer resins, such as castor beans.

There are two key advantages of using such plastics. Firstly, they aren’t made from fossil fuels, which are a depleting resource that requires millions of years to form. Secondly, the carbon footprint of producing biopolymers, from planting a seed all the way to formulating plastic resins, is typically much lower than with fossil fuel-based plastics. There is also a possible benefit that the biomass sources may also sequester atmospheric carbon during their growing stages too.

How This Applies to the Industry

Bioplastics is a fast-growing industry, with more and more bioplastic resins being made available, even for medical device applications. As demand increases and confidence grows in these technologies, the supply can be expected to increase too. Experimentation may be required in order to incorporate such materials into device development, but considering these materials as part of device design may yield a more sustainable product.

8: DESIGN FOR END OF LIFE

Definition

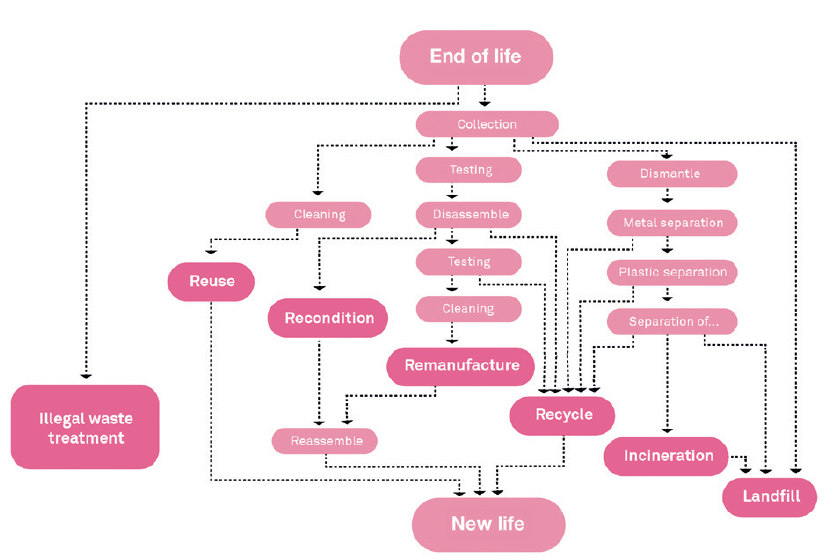

This design practice is concerned with designing a product with the end of its life in mind. It aims to build an understanding of what disposal or end-of-life processing is most relevant to the product. Having this mindset allows for more sustainable design choices to help reduce the environmental impact of medical waste. This can include aspects such as design for disassembly, recycling, re-use, remanufacture, energy recovery, repair and more (Figure 3).

Figure 3: Overview of end-of-life options and crucial steps in the end-of-life treatment.

“As governmental legislation and regulatory requirements evolve, medical device manufacturers are being required to take more responsibility for the full lifecycle of their products.”

How This Applies to the Industry

Alongside GHG emissions, medical device waste is another cause for concern. Due to its clinical nature, medical device waste is typically disposed of outside of municipal or domestic waste streams, most often in medical waste incinerators. Conventionally, design efforts are usually focused on design for manufacture and for commercialisation, with the product’s end of life often being an afterthought.

Designing for end of life is of increasing importance, particularly at earlier phases of medical device development, such as the concept generation phase. There is also the opportunity to reduce the carbon footprint of subsequent generations of products, as recycled material feedstock can have lower associated emissions than virgin materials. As governmental legislation and regulatory requirements evolve, medical device manufacturers are being required to take more responsibility for the full lifecycle of their products. The new expectation is set to be that you should be ready to look after your product from the start to the end of its life.5

SUSTAINABILITY IN MEDICAL DEVICE DEVELOPMENT

There is no easy path towards fully sustainable medical device development. For any progress to be made, however, it will be important for companies to join the discussion with a common understanding of the issue. As innovations in sustainable development progress, and as regulations, standards and legislation evolve, we can hope to see some meaningful progress reflected in the medical device and pharmaceutical industry.

REFERENCES

- “The 17 Goals”. United Nations Department of Economic and Social Affairs website, accessed Oct 2021.

- “For a Livable Climate: Net-Zero Commitments Must Be Backed by Credible Action”. United Nations Climate Action website, accessed Oct 2021.

- “Corporate Value Chain (Scope 3) Accounting and Reporting Standard”. World Resources Institute and World Business Council for Sustainable Development, Sep 2011.

- “What is a Circular Economy?”. Ellen MacArthur Foundation website, accessed Oct 2021.

- Peeters J, Dewulf K, “Design for End of Life: A Design Methodology for the Early Stages of an Innovation Process”. E&PDE12 Conference Proceedings, 2012, pp 185–190.