To Issue 176

Citation: Boerner M, “Safe and Skin-Friendly Manufacturing of Medical Wearables with Ultrasonic Welding”. ONdrugDelivery, Issue 176 (Sep 2025), pp 20–23.

Michael Boerner looks at the key factors for designing skin-friendly medical wearables and how to manufacture them safely, automatically and sustainably.

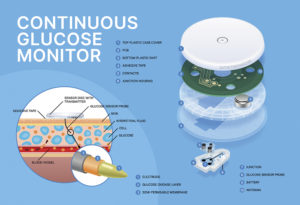

The rising global prevalence of diabetes is driving a rapidly increasing demand for medical wearable devices, such as continuous glucose monitors (CGMs) and patch pumps (Figure 1). These devices offer patients enhanced freedom, safety and, ultimately, an improved quality of life.

Figure 1: The appropriate joining technology is crucial for optimal wearing comfort and reliable functionality of medical wearable devices, such as CGMs and patch pumps.

However, studies indicate that up to 81% of users experience skin irritation from these wearables.1 This is often caused by allergens such as isobornyl acrylate (IBOA), commonly found in the chemical adhesives used in medical devices.2 Additionally, other factors can also compromise the comfort and functionality of medical wearables, such as the use of unsuitable materials or joining processes for plastic components.

SKIN-FRIENDLY WEARABLES START WITH THE DESIGN

To prevent skin irritation, product designers must consider the moisture vapour transmission rate (MVTR) during development. This factor significantly impacts both skin compatibility and comfort during wear; however, it can be effectively managed through the use of appropriate joining technology.

The MVTR measures the amount of moisture vapour that passes through a material within a day. A high MVTR value allows the skin to breathe more easily, reducing the risk of irritation. However, medical wearables, such as CGMs, which are worn directly on the skin, can limit breathability. This issue becomes particularly critical when stronger adhesive formulations or higher adhesive coating weights are used. These factors hinder moisture escape, increasing the likelihood of skin irritation.

“TO MINIMISE IRRITATION CAUSED BY PROLONGED USE OF MEDICAL WEARABLES, IT IS CRUCIAL TO CONSIDER MVTR EARLY IN THE PRODUCT DEVELOPMENT PROCESS.”

To minimise irritation caused by prolonged use of medical wearables, it is crucial to consider MVTR early in the product development process.

CRITICAL FACTORS FOR THE MVTR

Medical wearables are typically attached to the skin using a skin adhesive with a nonwoven backing, forming a skin-adhesive patch. The sensor or device is then affixed directly to this patch. Even when the adhesive plaster has a high MVTR, the device itself can still restrict or completely block the skin’s breathability.

Additional barriers may arise if unsuitable joining technologies are used to attach the sensor or device to the nonwoven material on the back of the skin patch. Traditionally, this has been achieved through heat sealing or adhesive bonding.

However, conventional adhesives and heat-based bonding methods often have limitations. The chemicals in adhesives can trigger allergic reactions and further restrict skin breathability. While additional sensor mounting tape or reactive adhesives can provide a secure hold, they also introduce another barrier, increasing the risk of skin irritation.

Thermal joining processes, on the other hand, can negatively impact the soft material properties of nonwoven patches, reducing their flexibility and comfort. Moreover, excessive thermal loads during joining can create microchannels that weaken the bond, compromising the device’s secure attachment to the wearer’s skin.

USING ULTRASONIC WELDING TO IMPROVE BREATHABILITY

Ultrasonic welding presents an innovative alternative to conventional bonding methods. This technology uses high-frequency mechanical vibrations to weld materials together at precise points. The heat generated is confined to these predefined joining zones, protecting the surrounding areas of the application.

This process offers several key advantages. As no chemical adhesives are required, the risk of allergic reactions caused by IBOA is eliminated. Additionally, the soft material structure remains intact, as thermal exposure is minimal and occurs only in the designated weld zone. The resulting bond is highly durable, ensuring a long shelf life.

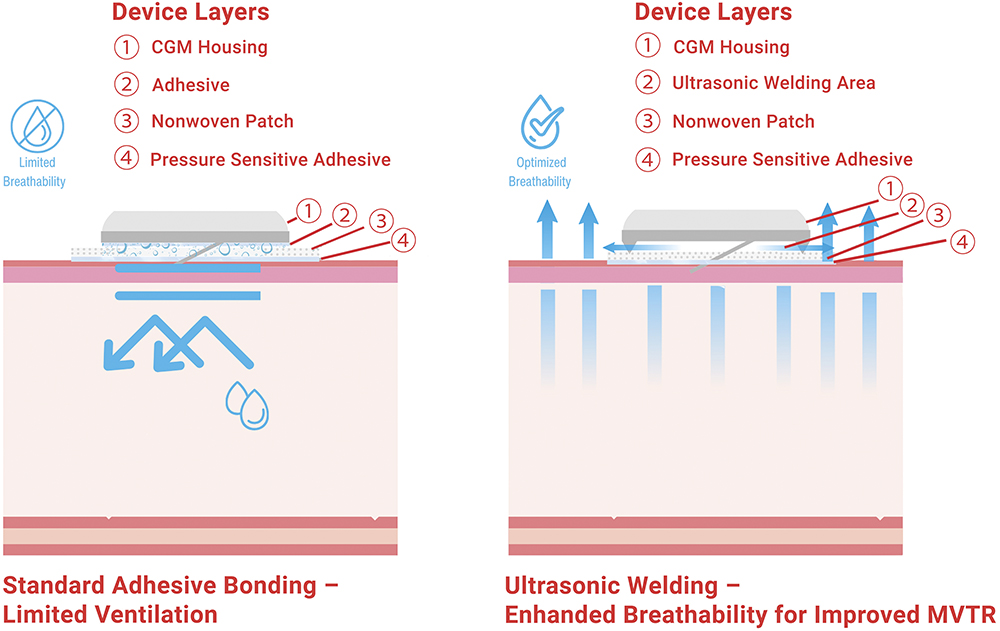

Furthermore, ultrasonic welding enables the integration of ventilation gaps and drainage channels, enhancing airflow and reducing the likelihood of moisture build up (Figure 2).

Figure 2: While using adhesives as a joining technology can restrict the skin’s breathability, ultrasonic welding makes it possible to include microchannels to ensure optimum MVTR.

CHOOSING THE RIGHT MATERIAL FOR MEDICAL WEARABLES

To date, medical wearables have been made primarily of polyvinyl chloride (PVC). PVC is robust, chemically resistant and inexpensive, but is made flexible by the addition of plasticisers, which poses risks for both the environment and the health of the patient.

Figure 3: Precise control of process parameters enables ultrasonic technology to join even sensitive components and parts hermetically and securely.

As such, manufacturers are increasingly switching from PVC to thermoplastic elastomers (TPEs). Even if PVC and TPEs differ fundamentally in their chemical composition, they have similar physical properties, which simplifies the switch. The benefits of TPEs are that they are naturally flexible, require no plasticisers and are more biocompatible (Figure 3).

DIFFERENT JOINING PROCESSES FOR TPE

When joining TPE components, the material’s smooth surface structure presents a key challenge. Bonding TPEs requires specialised adhesives that are chemically compatible and provide sufficient elasticity. However, these adhesives tend to be more expensive and complex to handle compared with conventional ones. Additionally, TPE surfaces often require chemical pre-treatment to ensure proper adhesion, adding extra production steps and costs.

Hot welding of TPEs also demands precise temperature control and specialised equipment, as excessive heat can damage the material. Furthermore, the smooth surface makes it difficult to achieve stable joints, as the melting properties of TPEs are less predictable than those of PVC.

“ULTRASONIC WELDING IS PARTICULARLY WELL-SUITED FOR JOINING PLASTICS SUCH AS TPEs.”

Ultrasonic welding is particularly well-suited for joining plastics such as TPEs. The precise application of energy enables a controlled and uniform fusion of the TPE components. In addition, this technology minimises material changes and ensures consistent quality of the products.

CHALLENGES WITH MATERIAL SELECTION

However, due to the unique properties of each material, not all plastics can be welded together with the same efficiency. When designing a component intended for ultrasonic welding, selecting the right material is the crucial first step towards a successful welding process.

All thermoplastic materials can be joined using ultrasonic technology. However, homogeneous (uniform) welding is only possible with identical thermoplastics.

The most commonly processed thermoplastics in ultrasonic welding include:

- Acrylonitrile butadiene styrene (ABS)

- Polystyrene (PS)

- Polypropylene (PP)

- Polyethylene (PE)

- Polyvinyl chloride (PVC)

- Polymethyl methacrylate (PMMA)

- Polycarbonate (PC).

Additives can also affect the weldability of thermoplastics – both positively and negatively. Additionally, various external factors influence how well plastics can be welded (Table 1).

| Negative Influences | Positive Influences |

| Additives (such as fire protection): Additives protect plastics from degradation caused by external influences. However, this also means that additives make it harder to process the plastic using ultrasonics. |

Glass fibres: Increase the stiffness, toughness and strength of the plastic, thus improving sound conductively, especially in semi-crystalline plastics. |

| Moisture (especially in polyamides): If the plastic has a high moisture level, it can evaporate during welding. This leads to gas bubbles in the joining area, resulting in porous weld joints. |

Glass beads: Increase the pressure resistance of the plastic, thus improving sound conductivity, especially in semi-crystalline plastics. |

Table 1: Positive and negative influences on plastic welding.

IMPROVED SAFETY IN MANUFACTURING THANKS TO REAL-TIME QUALITY CONTROL

A major advantage of ultrasonic welding is the precise control it offers throughout the entire joining process. Intelligent software within the generator regulates the operation, storing optimised welding parameters that have been determined through extensive laboratory testing.

Once the welding modules are integrated into the production system, these predefined parameters can be consistently and reliably replicated in every individual weld. This ensures a stable process, delivering high-quality connections with every cycle.

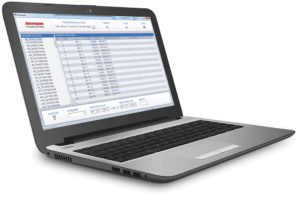

Figure 4: Seamless process monitoring makes the manufacture of medical wearables using ultrasonic technology process-safe and traceable.Figure 4: Seamless process monitoring makes the manufacture of medical wearables using ultrasonic technology process-safe and traceable.

The intelligent software controlling the welding process not only ensures hermetic seals but also enables manufacturers to implement digital quality control in their production. Because the component is in direct contact with the welding tool during the joining process, real-time data collection is possible. Up to 150 data points per weld are transmitted to the generator and stored, which can then be accessed from anywhere in the world. Analysing data from thousands of welds can help to identify valuable opportunities for further process optimisation, making production even more efficient.

Seamless process monitoring also enhances traceability. In the event of a product recall by the US FDA or similar regulatory body, defective products can be quickly and accurately identified (Figure 4).

GREAT POTENTIAL FOR AUTOMATED MANUFACTURING

Ultrasonic welding offers an ideal solution for high-volume manufacturing, thanks to its precise and automated process control. Unlike adhesive or heat-based welding systems, ultrasonic welding is ready for use immediately – without the need for tool heating or curing agents. This ensures consistent results from the very first weld.

A key advantage of this technology is its efficiency. Since no additional joining agents are required, time-consuming cleaning and regular maintenance are eliminated. This minimises system downtimes and maximises production output. Moreover, ultrasonic welding operates at extremely high speeds, creating strong connections in as little as 80–500 milliseconds, depending on the application.

Another significant benefit is its resilience to environmental influences. Adhesives, for example, often require recalibration when moved to a new production site, as temperature fluctuations during transport can alter their properties – sometimes leading to weeks of downtime.

Ultrasonic components, however, function reliably regardless of temperature changes or material batch variations. This eliminates the need for adjustments when relocating modules to different climates, allowing for seamless production transitions and immediate operational readiness.

SUPPORTING SUSTAINABLE PRODUCTION AND PRODUCTS

By switching to ultrasonic joining technology, manufacturers can enhance the sustainability of both their products and production processes. This is primarily possible because additional joining agents, such as adhesives, are no longer required. These chemical agents must first be produced, transported and heated – steps that consume large amounts of CO2, particularly if they need to be distributed globally.

The use of adhesives also means that medical devices are no longer made from a single material, preventing them from being integrated into the circular economy.

These negative environmental impacts do not apply to ultrasonic welding. The technology only requires energy for joining plastics, which can be sourced locally from renewable sources.

Furthermore, the energy usage can be precisely controlled, enabling a reduction of about 60% in energy consumption compared with alternative joining processes. This significantly improves the carbon footprint of manufacturing.

CONCLUSION

Ultrasonic welding offers a promising solution to address the challenges faced in the production of medical wearable devices. By eliminating the need for chemical adhesives, which are often responsible for skin irritation, and by providing precise control over the joining process, this technology can ensure both skin compatibility and product reliability.

Additionally, the energy-efficient and sustainable nature of ultrasonic welding makes it an ideal choice for manufacturers aiming to meet the growing demand for medical wearables while enhancing patient comfort, safety and quality of life. With its ability to reduce the environmental impact and improve the overall functionality of wearables, ultrasonic welding paves the way for a more sustainable and user-friendly future in medical device manufacturing.

REFERENCES

- de Groot A et al, “Allergic contact dermatitis caused by glucose sensors and insulin pumps: A full review”. Contact Dermatitis, 2024, Vol 92(2), pp 87–112.

- Lombardo F et al, “High Frequency of Dermatological Complications in Children and Adolescents with Type 1 Diabetes: A Web-Based Survey”. J Diabetes Sci Technol, 2021, Vol 15(6), pp 1377–1381.