To Issue 182

Citation: Pircher D, Moser L, “Time to Market: Increased Customer Value Through Global Ramp-Up Excellence”. ONdrugDelivery, Issue 182 (Jan 2026), pp 101–106.

Visit BAUMANN Medical at Pharmapack Paris! – Stand 4G41

David Pircher and Leander Moser discuss the advantages of having a global presence, which combines both local expertise and technical excellence with worldwide co-ordination of supply to deliver consistent and quality solutions.

The global demand for springs and stampings in medical devices is rising rapidly, driven by trends such as glucagon-like peptide-1 (GPL-1) therapies, needlestick protection and self-treatment solutions. This growth coincides with complex supply chains and a fragmented global market. In this environment, scaling effectively from concept to global production is a key competitive advantage. Partners value not only technical capability, but also assurances that projects will move seamlessly from development to be implemented globally. They seek reliability, risk mitigation and co-ordinated expertise to navigate regulatory complexity and supply chain volatility.

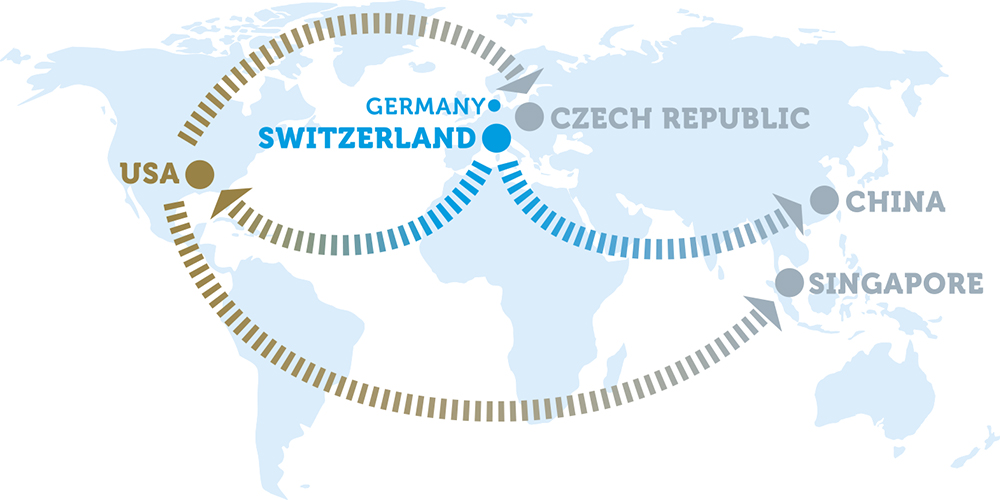

Through strong collaboration, BAUMANN Medical has established a best-practice setup that maximises value for global projects. Combining technical excellence with local expertise and global unity, the company provides support at every stage of the lifecycle. Advanced engineering and material knowledge ensure compliance and performance, while regional teams provide on-the-ground support using standardised procedures. Co-ordinated manufacturing footprints deliver consistent quality and continuity, even in fragmented markets. Integrated supplier management reduces complexity and strengthens resilience, while proactive strategies – dual sourcing, capacity planning and contingency measures – safeguard against disruptions.

These aspects are all intended to support customers in the best way possible and allow for rapid adjustment of production levels. For pharmaceutical companies in particular, as well as contract and device manufacturers, having a partner with a global footprint is crucial to mitigate geopolitical risks and optimise costs.

“GLOBAL PROJECTS IN THE MEDICAL DEVICE SECTOR NEED MORE THAN AN INTERNATIONAL PRESENCE – THEY REQUIRE A STRUCTURED APPROACH FROM INITIAL CONCEPT TO FULL-SCALE PRODUCTION.”

TECHNICAL EXCELLENCE – THE FOUNDATION FOR GLOBAL OPERATIONS

Global projects in the medical device sector need more than an international presence – they require a structured approach from initial concept to full-scale production. Scaling begins with a robust design supported by simulation tools such as finite element method (FEM)/finite element analysis, ensuring predictable performance and compliance before physical prototypes are built. This technical foundation reduces risk and accelerates development.

Figure 1: Five key principles for global scaling in drug delivery.

Material expertise and process validation are critical for consistent quality across global sites. Biocompatibility, durability and regulatory approval drive material choices, while validated processes guarantee repeatability and reliability. Standardisation of equipment and workflows enables efficient technology transfer, training of local teams and rapid ramp-up in new markets without compromising quality.

Technical excellence means mastering processes, continuously improving them and adapting to evolving requirements. This systematic approach ensures sustainable quality and international competitiveness. To elaborate on the crucial role of technical excellence, the next section presents five key elements of global operations from a non-exhaustive, cross-sectional perspective (Figure 1).

Global Standardisation – The Common Language of Global Production

Standardisation underpins every successful ramp-up. Consistent processes, equipment and documentation enable the organisation to operate as one globally – speaking a common language across cultures and time zones. Applying standardised procedures and guidelines is more essential than ever. Global customers expect suppliers to guarantee identical quality standards worldwide, which builds trust in their reliability and efficiency.

BAUMANN Medical has advanced standardisation so that the same production process runs identically at every site. The result: a harmonised network that reduces complexity, ensures reliable planning and delivers consistent quality for original equipment manufacturers (OEMs) and contract manufacturers. Core processes and material flows are standardised, while certain steps are adapted to local circumstances – for example, fully automated packaging in one location and semi-automated packaging in another where labour costs are lower.

This balanced approach combines global consistency with local flexibility, ensuring efficiency without compromising quality. Standardisation drives operational excellence, mitigates geopolitical dependencies and strengthens supply chain resilience.

From Simulation to Validation – Turning Precision into Predictability

Simulation and virtual testing are essential parts of BAUMANN Medical’s development process, helping the company to understand how materials behave even before the first prototype is built.

Using modern simulation technologies such as FEM can accurately predict material behaviour, stresses and deformations early in the development phase. This forward-looking approach reduces development cycles with repeated prototype builds, minimises waste and provides guidance for process steps and critical parameters. This is a crucial building block in making quality predictable – regardless of whether a component is manufactured in Europe, Asia or America.

Material Expertise – Balancing Performance and Precision

Understanding various technical requirements – such as spring relaxation and its dependence on material properties, process parameters, stress state and storage time – is critical for reliable medical device design at an early stage.

However, selecting the right material is not only a technical decision but also a strategic one. The selection directly influences the performance, service life and efficiency of each product. Besides the technical aspects, supply chain management should consider commercial, logistical and supply chain risk aspects.

Consistent Quality Through Process Validation

Process validation ensures that processes are ready for series production – stable, predictable and under control. However, process validation is far more than a formal step to prepare for series production. In combination with the standardised setup, this ensures that the manufacturing process is reproducible, scalable and robust. This means applying the same standards and achieving the same results globally.

Figure 2: Quality in production – logbook entries.

Validation not only achieves technical stability, but also builds trust. Above all, this applies internally to the co-operation between sites, but it also extends to customers. Comprehensive control over the processes delivers both quality and reliability. This reliability is one of the key reasons why the partnership is highly valued within global supply chains (Figure 2).

In-House Expertise and Equipment Development

Another highly relevant factor of technical excellence is the development and building of machinery. BAUMANN Medical builds machines for its core processes in-house, which provides greater flexibility and full control over its production capabilities.

By designing and constructing its equipment internally – such as for wire cold forming or packing – technological agility and innovation are assured. Additionally, industrialising new processes quickly, implementing technological advancements seamlessly and maintaining consistent standards across all locations provide significant stakeholder benefits.

LOCAL EXPERTISE, GLOBAL UNITY – WHY FOOTPRINTS MATTER

In the medical component industry, having a local presence is more than a logistical advantage – it is a strategic necessity. Regulatory compliance, supply chain resilience and cultural understanding all depend on having teams embedded in key markets.

This principle extends to a globally connected approach – each site operates as part of one network, aligned by shared standards, synchronised processes and a collaborative culture. Documentation is created with a global mindset, ensuring applicability across locations. Every procedure, test and process step is locally compliant yet globally transferable – facilitating knowledge transfer and continuous improvement.

Global transfers go beyond moving machines – they translate customer expectations into timelines, validated processes and trained teams. Success demands clear understanding of volumes, deadlines and product maturity, with resources aligned across infrastructure, materials and people.

Embracing global diversity combines ideas and expertise, forming the cornerstone of every ramp-up and enabling the network to deliver optimal outcomes worldwide (Figure 3).

Figure 3: Experts in BAUMANN Medical’s factory.

Scaling Global Projects: What Really Drives Success

Successfully scaling global projects requires early alignment and disciplined execution. It begins with a clear understanding of customer expectations – what needs to be delivered and by when, whether considering prototypes, performance qualification batches or commercial products. This clarity drives the planning for transfer and ramp-up, ensuring infrastructure, raw materials, equipment, processes and trained personnel are ready on time.

Clear mapping of dependencies between internal work packages, as well as dependencies on external partners and milestones, ensures full transparency on schedule impact. Critically, identifying a path forwards, allows for proactive risk management and keeps the project on track.

“ACTING AS ONE GLOBAL TEAM AND INVOLVING

THE RECEIVING SITE EARLY IN THE PROCESS SECURES SMOOTH KNOWLEDGE TRANSFER AND OWNERSHIP, REDUCING DELAYS.”

Close alignment with all stakeholders guarantees flexibility to adapt to changing needs while maintaining timelines. Acting as one global team and involving the receiving site early in the process secures smooth knowledge transfer and ownership, reducing delays. To achieve this, three pillars are essential:

- Standardisation: Implement standardised manufacturing lines and systems across all locations to ensure consistency, efficiency and quality.

- Competence Centre: Establish a central competence centre (e.g. BAUMANN Medical Switzerland) as the hub for expertise, best practices and technical support.

- Global Knowledge Transfer: Build a strong global team to drive effective knowledge transfer, ensuring processes and skills are replicated seamlessly worldwide.

Confirming process and site readiness before transfer, supported by globally applicable documentation, ensures consistency across locations. Multi-line validation delivers uniform quality globally. Robust, early preparation accelerates implementation, minimises risk and safeguards investments (Figure 4).

Figure 4: Scaling global projects.

Selecting a partner with proven global experience adds resilience and efficiency. Ultimately, success relies on a shared understanding of scope, expectations and timelines, combined with flexibility to manage the unexpected and to shift smoothly during ramp-up.

SUPPLIER MANAGEMENT – THE BASIS FOR QUALITY AND RELIABILITY

Another key component of a strong global footprint is the careful selection and management of suppliers. Supplier management plays a critical role, especially in an industry where individual components consist of a single material, such as stainless steel or carbon steel, that is purchased, precisely machined and then further processed into high-precision parts.

The ability to procure raw materials and other production materials competitively in the respective countries or regions where these materials are sourced is a key factor for success. Local purchasing of reliable raw materials not only ensures stable cost structures but also increases resilience to global price fluctuations and supply constraints.

For BAUMANN Medical, this means less dependence on international supply chains, greater planning security and even closer co-ordination with regional partners. The combination of global quality standards and regional procurement creates a robust foundation for reliable processes, stable supply and long-term customer trust (Figure 5).

Figure 5: Warehouses in the US.

Supply reliability in healthcare is non-negotiable. Patients depend on uninterrupted availability and OEMs require assurance that their partners can deliver – even during periods of market volatility. Achieving this level of reliability necessitates building resilient supply chains, supported by contractual commitments and proactive risk management strategies.

ECONOMICAL PERSPECTIVE – KEY ELEMENTS FOR BEST PRACTICE

In today’s highly regulated, competitive medical device industry, success requires more than technical expertise – it demands seamless collaboration across the supply chain. Managing relationships between global OEMs and contract and design managers is now a strategic priority for delivering quality, reliability and innovation at scale.

OEMs often work with multiple contract manufacturers to meet global demand and compliance, but co-ordinating partners worldwide is complex. It requires clear communication, standardised processes and strong governance to ensure consistent quality and adherence to timelines.

Operational efficiency is critical; standardised systems reduce complexity, minimise waste and optimise resources – lowering the total cost of ownership. Markets face sudden shifts in demand due to regulatory changes, launches or global health events. Manufacturers must scale up or down without compromising quality or delivery.

Global competence centres and knowledge transfer accelerate time-to-market, enabling rapid ramp-up and consistent quality. Multiple locations solve logistical challenges, cutting freight costs and improving delivery times.

Preventative measures and local presences mitigate geopolitical risks, shorten lead times and reduce the carbon footprint – combining risk management with sustainability. BAUMANN Medical’s global governance and proven frameworks strengthen reliability, ensure compliance and deliver predictable outcomes that protect investments and improve profitability.

CONCLUSION

Global ramp-up excellence is more than scaling production – it is about creating customer value through technical mastery, standardised processes and seamless knowledge transfer. In a fragmented medical device market, success depends on combining global consistency with local flexibility, ensuring compliance, reliability and speed. BAUMANN Medical’s approach integrates advanced engineering, material expertise and in-house equipment development with a harmonised global footprint and strong supplier management. This enables rapid time-to-market, risk mitigation and cost optimisation, which is critical for OEMs and contract manufacturers facing regulatory complexity and volatile demand. By acting as one global team, supported by competence centres and proven governance, BAUMANN Medical transforms complexity into clarity, delivering predictable outcomes and sustainable growth. It is not just about components – it is about enabling global success through partnership and shared expertise.