To Issue 179

Citation: Plankenhorn B, “Circular Design for Springs and Pressings in Drug Delivery Devices”. ONdrugDelivery, Issue 179 (Oct/Nov 2025), pp 44–47.

Bianca Plankenhorn discusses how sustainability is becoming an increasingly prominent and important part of the drug delivery industry, and how collaboration across the value chain – including steel spring and stampings manufacturers such as Lesjöfors – is critical for the industry to achieve its climate and emissions goals.

Throughout 2025, the number of discussions and events focused on circularity and sustainable solutions have multiplied – the concept of a circular economy is gaining momentum. However, despite the growing attention, Circle Economy’s (Amsterdam, the Netherlands) Circularity Gap Report for both 2024 and 2025 highlights that concrete initiatives remain limited.

“FOR MANUFACTURERS WORKING WITH STEEL MATERIALS AND COMPONENTS, THERE ARE ALREADY OPPORTUNITIES TO EMBRACE MORE CIRCULAR APPROACHES.”

For manufacturers working with steel materials and components, there are already opportunities to embrace more circular approaches. Innovation and collaboration between customers, suppliers and the broader value chain are essential to unlocking this potential.

CIRCULARITY AND GLOBAL BUSINESS

In today’s environment of complexity, volatility and uncertainty, efficiency and careful management of finite resources are becoming critical. Building resilient supply chains with a long-term perspective is now a key strategic priority. Equally, the urgency of moving towards fossil-free or low-carbon alternatives is accelerating the shift from linear to circular value streams.

Circularity is no longer a fringe idea – it is increasingly embraced by both producers and consumers. Across multiple industries, businesses are developing mature strategies that link circular solutions to economic value creation. Within the EU, the circular economy is a core element of the European Green Deal. The EU’s Circular Economy Action Plan (2020) explicitly connects business competitiveness with the transition to environmentally friendly products and services.

THREE PILLARS OF CIRCULARITY

At its core, circularity is built on three pillars – reduce, reuse, recycle. From another angle, it can be viewed as efficiency, sufficiency and consistency. Circularity encompasses a wide range of actions, from eco-design in production and consumption, to renewable energy use, biodiversity protection and more. By shifting from the traditional take-make-waste model to a circular approach, businesses can create value while protecting nature and benefiting society through collaboration and innovation.

For industry as a whole, the circular economy is set to be a gamechanger. However, progress remains slow, with secondary materials accounting for only 6.9% of global consumption in 2025.1 In the healthcare sector, opportunities are particularly evident in eco-design, waste reduction, longer material use, reduced reliance on single-use plastics, renewable resources and value-chain take-back programmes.2 Some of the main areas of focus for circularity include:

- Carbon Footprint: Inventory and target setting for reducing carbon dioxide emissions across the value chain and product lifecycle

- Waste Handling and Recycling Streams: Holistic waste management and creation of new value-added streams by reusing or recycling residual materials

- Supplier Development and Co-operation: Strategic push-and-pull effects along the value chain, supported by targets and project-based collaboration

- Circular Design: Implementing eco-design strategies and principles in daily practice

- Innovation: Encouraging new ideas through co-operation, knowledge-sharing and synergies.

Figure 1: Lesjöfors has embedded sustainability as a core aspect of its products.

LESJÖFORS’ APPROACH

As a supplier to the medical device and drug delivery systems sector, Lesjöfors has embedded circularity into its sustainability strategy, with innovation, resource efficiency and circular design being integral to its sustainability focus areas (Figure 1). Lesjöfors does not use the term “environmental, social and governance activities”, instead using the term “sustainability focus areas”. This makes it easier to engage with the company’s employees internally and its partners externally about what it wants to achieve. Key milestones that Lesjöfors has met so far include:

- Validation of near-term science-based targets in April 2024, making Lesjöfors the first in its industry to achieve this milestone

- Recognition in sustainability ratings such as CDP (London, UK) and EcoVadis (Paris, France), which support its continuous improvement processes

- Conducting its first lifecycle assessments in 2023 and 2024 (Figure 2), leading to the creation of its own methodology for carbon footprint calculations at the product level.

Lesjöfors operates more than 50 locations worldwide. Each site is addressing emissions reduction, renewable energy adoption and opportunities for collaboration in procurement, waste, recycling and transport. The company’s product carbon footprint (PCF) methodology uses a bottom-up approach, with calculations based on specific product emissions, building on data gathered during the Science Based Targets initiative’s (London, UK) validation process.

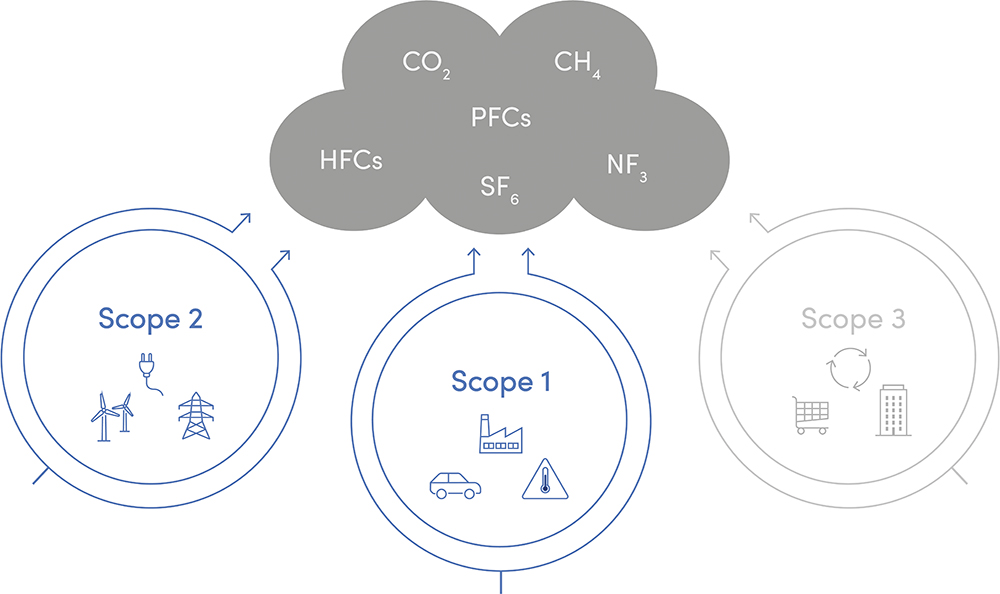

Figure 2: Carbon emission scopes for a lifecycle assessment.

ECO-THOUGHT PRINCIPLES

At Lesjöfors, sustainability is integrated from the outset of product development, regardless of customer demand. The company treats this mindset as standard practice and a prerequisite for achieving its ambitious emissions reduction goals, while also positioning itself as a leading supplier of springs and pressings for drug delivery systems.

This mindset is reinforced by Lesjöfors’ eco-thought principles, rooted in decades of technical expertise and aligned with the frameworks of the Ellen MacArthur Foundation (Crowes, UK) and EU Circular Economy Action Plan. The company’s engineers also account for practical factors such as application requirements, installation space and customer-specific needs (Figure 3). Trade-offs are often necessary – for example, reducing weight may lower transport emissions but could compromise component longevity.

Figure 3: Lesjöfors ensures that practical considerations are taken into account, such as installation space and customer-specific requirements.

“TOGETHER, ECO-THOUGHT PRINCIPLES AND PCF CALCULATIONS ENRICH LESJÖFORS’ PRODUCT OFFERING, ADDING VALUE FOR CUSTOMERS, SUPPORTING MORE INFORMED CONVERSATIONS WITH SUPPLIERS AND OPENING OPPORTUNITIES FOR JOINT SUSTAINABILITY INITIATIVES.”

Together, eco-thought principles and PCF calculations enrich Lesjöfors’ product offering, adding value for customers, supporting more informed conversations with suppliers and opening opportunities for joint sustainability initiatives. By modelling scenarios for PCF improvements, Lesjöfors not only advances its own climate transition plan but also helps customers to reduce emissions and improve supply chain sustainability. Collaboration between the company’s buyers and sales teams ensures that these efforts are embedded in practice.

THE ROLE OF STEEL AND COLLABORATION

Although steel products initially appear to have a higher environmental impact, they are inherently circular, being up to 100% recyclable. Steel is energy-intensive to produce and heavier than plastic alternatives, but its recyclability, supported by its magnetic characteristics, makes it a key circular material.

Currently, recycling rates for standard steel products remain too low and must be improved. By comparison, plastics are lighter and highly functional but present significant recycling challenges.

Figure 4: Collaboration is a key part of achieving emission reduction goals for drug delivery devices.

As a steel and metal component provider, Lesjöfors plays a critical role in advocating for a greater proportion of recycled content in raw materials and supporting the development of sustainable, circular steel solutions. When considering the carbon footprint of Lesjöfors’ products, the highest impact typically comes from raw materials, followed by emissions from production, external processes and transport.

Lesjöfors has built platforms for action with its strategic suppliers, requiring data on sustainability strategies and PCFs, as well as solutions with higher recycling shares and lower emissions. Early successes from the approach include customer projects with clear targets for emission reductions (Figure 4).

DRIVING SUSTAINABILITY IN DRUG DELIVERY SYSTEMS

In drug delivery system projects, Lesjöfors addresses sustainability through PCF calculations, hotspot identification and collaborative eco-design. These conversations create opportunities for joint value creation with customers and suppliers alike. The company aims to be number one in its industry for a more sustainable future, and that means being at the forefront of sustainable innovation.

REFERENCES

- “The Circularity Report 2025”. Circle Economy, May 2025.

- “EFPIA White Paper on Circular Economy”. EFPIA, Jul 2020.