To Issue 164

Citation: Schmidt P, “From Precision to Perfection: New On-Body Delivery System Testing Solutions”. ONdrugDelivery, Issue 164 (Sep 2024), pp 6–8.

Peter Schmidt details the advantages ZwickRoell’s integrated testing systems offer for ensuring precise and accurate testing of on-body drug delivery systems, including the prevention of static charge and the company’s advanced camera-based measurement systems.

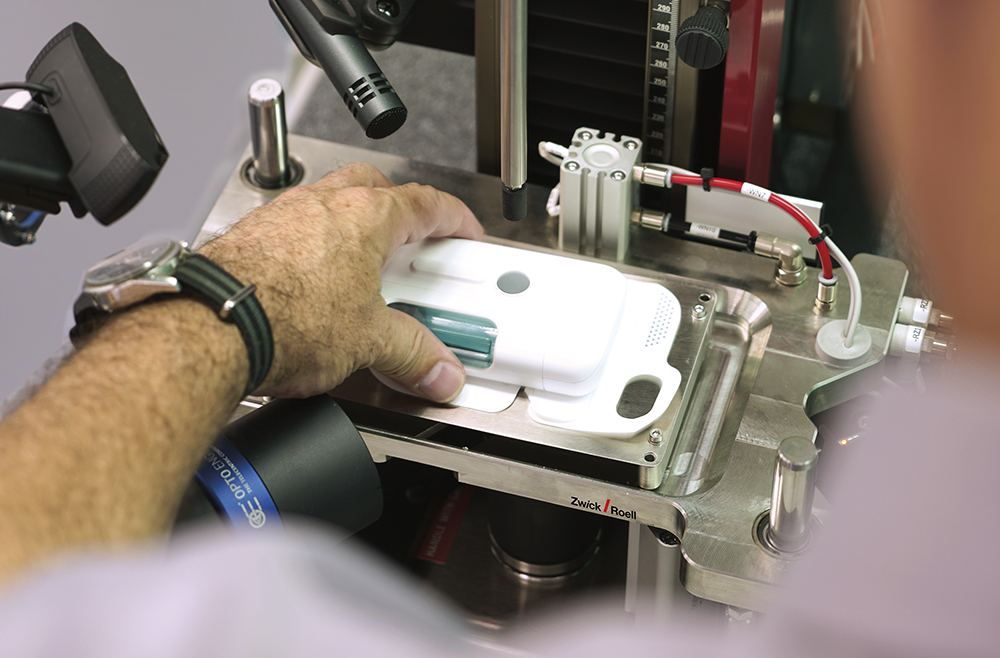

In the medical industry, wearable injectors and on-body delivery systems (OBDSs) are playing an increasingly important role in the treatment of cancers, autoimmune diseases, rare diseases and neurological disorders. These devices offer a means to efficiently and precisely administer drugs in effective doses over longer periods of time, especially for patients who require regular injections (Figure 1).

Figure 1: OBDSs are an efficient and patient-friendly approach for injections over a longer period of time.

ZwickRoell testing systems support and set new standards in standard-compliant testing for these drug delivery devices. The company’s systems provide users with unique advantages for the development of both standard and automated testing systems, with a focus on reproducible, traceable results, as well as reliability, safety and efficiency.

ZwickRoell has installed nearly 200 autoinjector testing systems worldwide and is continuously working to further raise standards in OBDS testing as well. The administration of highly viscous biologics continues to pose a significant technical challenge to the industry, so OBDSs must be able to effectively handle drug reservoirs with volumes ranging from 2 mL to up to more than 20 mL, and achieve delivery rates of 0.01 mL to over 60 mL per hour. These devices vary in their duration of use from minutes to several hours and often integrate advanced communication technologies, such as Bluetooth and near-field communication (NFC), to improve patient care. These technical requirements emphasise the need for innovation in the design of wearable injectors, both in single-use and reusable systems.

“A unique feature of ZwickRoell’s testing systems is the ability to achieve sequential results on a single specimen.”

A unique feature of ZwickRoell’s testing systems is the ability to achieve sequential results on a single specimen. As a result, all the necessary tests that were previously performed separately can now be carried out in a single, coherent test sequence. This not only saves time, but also reduces the number of inaccuracies caused by user influences, as the specimens do not have to be moved between different tests, thus guaranteeing traceable and reproducible results.

CHALLENGES IN CALCULATING RESULTS

The injection of drugs, highly viscous drugs in particular, poses a number of technical challenges that must be carefully addressed to ensure their safety and effectiveness during treatment. A major challenge is the need to avoid static charge during the testing process, which can greatly impair the precision of the weighing results. In addition, the crystallisation of the drug upon contact with air poses a challenge. This clogging effect can sometimes also affect the administration itself. Equally problematic is the evaporation of the drug during the injection process, which can take up to 60 minutes and can falsify the dosage. The OBDS testing system from ZwickRoell prevents these effects via a special test methodology employed throughout the entire testing process.

Highly accurate measurement of the injection depth is crucial for ensuring that the drug is applied exactly where it is needed in the body. Precise determination of the total injection volume, including the last drop, is equally important for guaranteeing the required dose for therapy and avoiding waste. These requirements call for advanced technologies and precise engineering to maximise effectiveness and patient safety.

DAILY CHECKS FOR ALL SENSORS

Before each new test job, it is essential to check whether all the sensors used are working and providing reliable results. An error in the results chain can have fatal consequences for the quality of the results and, therefore, for production or delivery, creating significant additional costs for the development programme.

“ZwickRoell offers easy-to-use and reliable daily check tools for all sensors used in the testing of autoinjectors to ensure systematic functional reliability before each job and before each time a product to be tested is changed.”

As such, ZwickRoell offers easy-to-use and reliable daily check tools for all sensors used in the testing of autoinjectors to ensure systematic functional reliability before each job and before each time a product to be tested is changed. The daily check results are linked to the test programme and ensure that, in the case of a check failure, the test job cannot be performed.

SPECIAL BEAKER PREVENTS STATIC CHARGE

Another highlight of ZwickRoell’s testing systems is the integrated, high-precision scale for obtaining extremely accurate test results. This precision is critical for determining the precise amount of the drug injected over the entire injection (injection profile) and for ensuring that the dosing meets all required standards. ZwickRoell has developed a sophisticated and clever solution to avoid falsification of results and thereby continually set high standards, including in the implementation of OBDS tests.

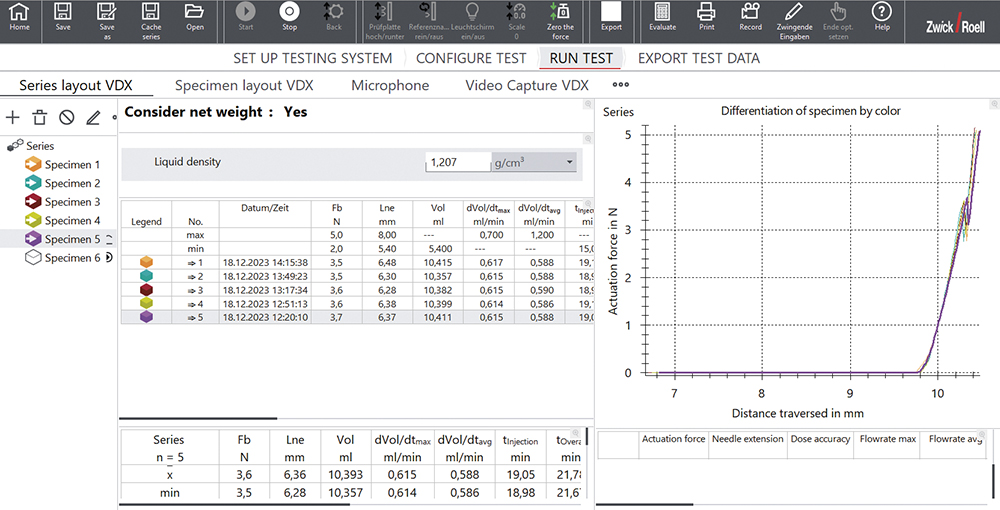

CAMERA-BASED MEASUREMENT AND VIDEO CAPTURE

Camera-based measurement (VDX) is a revolutionary method for the precise recording of injection parameters (Figure 2). This system provides more accurate results than traditional methods as it is not affected by injection mist or spray. A key feature is the ability to measure injection depths for needle lengths between 2.5 mm and 15 mm with an impressive accuracy of less than ±0.05 mm. Additionally, it enables the measurement of the injection time with a minimum duration of less than ±0.05 seconds to record extremely fast injections, as is the case with emergency injectors.

Figure 2: ZwickRoell’s OBDS testing system using highly precise VDX.

Another advantage of this system is synchronised video capture, which enables the entire injection process to be visually documented and recorded synchronously with other measurement data. This is an integral part of the quality control measurement process. The unique ability to calibrate the camera-based system also increases the reliability of the test results. Flexible adjustment of the field of view also enables the width of the liquid injection angle to be recorded precisely, making this measuring system an indispensable tool.

“ZwickRoell’s VDX system ensures precise monitoring and analysis of every phase of the injection, from activation of the injector to completion of delivery.”

ZwickRoell’s VDX system ensures precise monitoring and analysis of every phase of the injection, from activation of the injector to completion of delivery. The high-resolution camera provides detailed insights that are essential for calculating results, quality control and error analysis. This technology also enables all results to be recorded accurately and to immediately identify any deviations.

Figure 3: A modular set-up enables adaptation when changes are necessary.

MODULAR DESIGN AND CUSTOMISATIONS

As well as standardised solutions, ZwickRoell also offers customised systems that can be quickly and flexibly tailored to meet a customer’s specific needs. The ability to quickly configure testing machines for different standard changes, testing requirements and methods, whether for research and development or quality control, makes these systems particularly flexible (Figure 3). This is why ZwickRoell’s development team works so closely with its customers – to make sure that their specific requirements are always met. Each solution aims to deliver the best possible modular structure and can therefore be individually adapted to a customer’s specific requirements, making them an ideal solution for a wide range of OBDS testing requirements. The systems cover any challenge that could possibly arise when testing OBDSs and, therefore, offer comprehensive solutions for the pharmaceutical industry.

SECURE DATA AND SEAMLESS TRACKING

ZwickRoell offers solutions for managing data as well as complying with legal requirements such as US FDA 21 CFR Part 11. The software package for testing injectors with ZwickRoell’s testXpert III software enables complete traceability and user management to ensure that all data is tamper-proof and cannot be altered (Figure 4). The integrity of the data and user management are crucial for compliance with legal requirements and, consequently, the security of users and patients.

Figure 4: ZwickRoell’s testXpert software displays the key test results at a glance.

Previous article

ENHANCING THE PATIENT AND NURSE EXPERIENCE IN LARGE-VOLUME SUBCUTANEOUS DRUG DELIVERYNext article

CCBio’s Quick Dose On-Body Injector