Citation: Resker T, “Options for Activation of Battery-Operated Medical Devices”. ONdrugDelivery, Issue 124 (Sep 2021), pp 64–66.

Tim Resker looks at new technologies for powering on battery-operated drug delivery devices while considering battery drain, ingress protection and user-friendliness.

Battery-operated, wirelessly connected devices are becoming increasingly pervasive in today’s society. Driven forward by advancements in wireless and battery technologies, coupled with increasingly miniaturised electronic components that consume less power and cloud-based services ready to collect, analyse and disseminate data, these devices commonly instantiate themselves as handheld, wearable or implantable medical devices, such as those used for drug delivery.

“There are three basic options for powering on these devices at the point of use or deployment. For each of these options, essential variables for consideration are battery current drain, size, ingress protection and user-friendliness.”

Whether the device is a drug delivery device or vital sign monitor, whether it is handheld, wearable, ingestible or implantable, all share a set of common requirements: small size, long life, reliability and ease of use. One of the key design aspects of these products is how to power the device on when needed.

Powering on a medical device only when it is needed (or keeping it powered down when not in use) is vitally important because designers want to use the smallest, lowest cost battery possible. For this reason, extending battery life is always a design goal; battery drain must be minimised during use as well as before it has been powered on.

One popular example is continuous glucose monitors (CGMs), which are prescribed to help patients manage their diabetes. These devices adhere to the patient’s body, continuously monitoring glucose levels. The resulting data is wirelessly transmitted to the patient, doctor and/or insulin pump. CGMs must be very small, waterproof, easy to attach and have a reasonably long life before they run out of battery power.

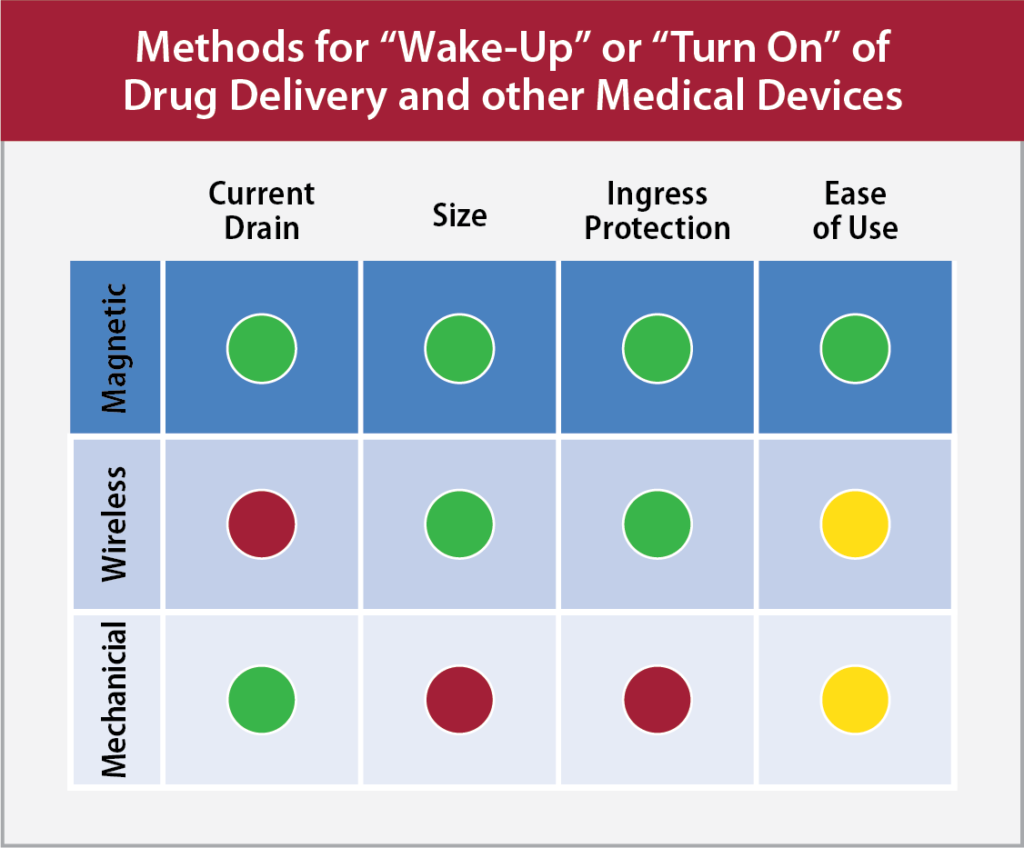

There are three basic options for powering on these devices at the point of use or deployment. For each of these options, essential variables for consideration are battery current drain, size, ingress protection and user-friendliness (Figure 1).

Figure 1: The TMR magnetic sensor offers almost zero power consumption in an ultra-miniature package size, and its contactless “power on” capability promotes ease of use.

“…mechanical switches score highly in terms of current consumption but very low relative to ingress protection, size and ease of use.”

ELECTROMECHANICAL

The first “power on” option is electromechanical – the common “switch”. This option is the means for powering on most battery-operated electronic devices, such as laptops and phones. Although switches come in many forms, (e.g. pushbutton, slider or toggle) they operate on the same principle of opening and closing a mechanical contact to allow current to flow (when closed) or completely prevent it from flowing (when open). Regarding current drain, the electromechanical switch is highly efficient because it is a passive device that consumes no power. However, in terms of size, mechanical switches are a poor option, especially given the size constraints of many wearable, ingestible and implantable medical devices and other small Internet of Things devices. In terms of ingress protection (or the need to have a device that is impermeable to water and humidity), mechanical switches are not the best option because designing a switch that can be mechanically moved by the user into on/off positions while maintaining impermeability is challenging. Lastly, the consideration of user-friendliness, or ease of use, rates poorly with mechanical switches for two reasons. Firstly, there is a clear conflict between the requirement for a patient to manually activate a switch themselves and the design goal of the device having “out-of-the-box turn-on” – one demands manual activation, the other automatic. Secondly, a very small mechanical switch, necessitated by a very small device, could pose a problem for users’ ability to actually move the switch between the on and off positions, thereby reducing usability. In summary, mechanical switches score highly in terms of current consumption but very low relative to ingress protection, size and ease of use.

WIRELESS

Wireless power on is the second option to analyse. Because the devices already have wireless capabilities for data transmission, designers could technically use that same wireless capability to power on a device from a mobile phone app. From an ingress protection standpoint, powering on wirelessly is rated very highly, as well as from a size standpoint, as no additional components need to be added to the device for this functionality. However, from a current drain standpoint, wireless power on scores extremely low because a wireless receiver inside the device must be powered on to receive a signal to power on. For this reason alone, wireless power on is rarely used for devices that have stringent battery life requirements.

“Many new devices are designed with new tunneling magnetoresistive (TMR) sensing technology, which offers both very small size (as small as an LGA-4) and extremely low power consumption, similar to the reed switch.”

MAGNETIC

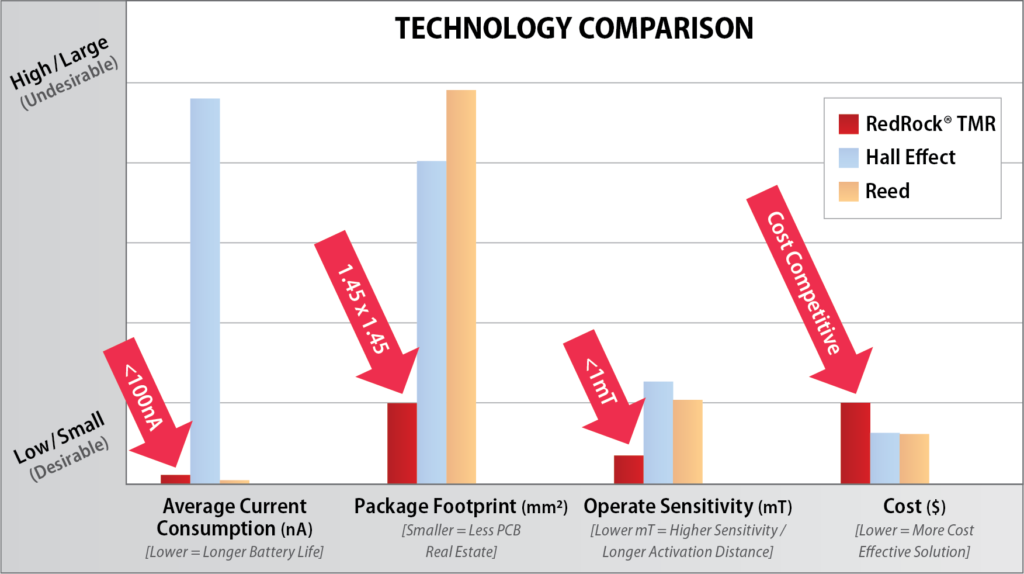

The third option is the use of a magnetic sensor inside the device to initiate the power on function. In this case, a magnetic field is applied to the sensor to trigger the power on. The magnetic field is typically produced by a magnet located within the product’s packaging or in an auxiliary component to the device, such as an applicator for a CGM. The magnetic field can also be applied by the user swiping across the device with a handheld magnet. Magnetic sensing scores very highly for ingress protection because it is a “contactless” method. Magnetic sensing also scores very highly in ease of use – especially when the magnet can be embedded in the device packaging, enabling “out-of-the-box power on”, or in an auxiliary component to the device, such as an applicator. Sometimes the device itself is designed as two components that must be connected at the time of deployment. In terms of current drain and size, the desirability of magnetic sensing depends entirely on the magnetic sensing technology in question (Figure 2). Older, more traditional magnetic sensing technology types were either small in size but high in power consumption (Hall effect) or large in size with zero power consumption (reed switches). However, many new devices are designed with new tunneling magnetoresistive (TMR) sensing technology, which offers both very small size (as small as an LGA-4) and extremely low power consumption, similar to the reed switch. In effect, TMR sensors offer the “best of both worlds”.

Figure 2: Magnetic sensing technology comparison.

CONCLUSION

With the current onslaught of new devices designed to be easier, safer, contactless and/or remotely operable, electronic designers are having to adopt new technologies to keep up with the evolving requirements of battery-operated medical and drug delivery devices. In terms of best capabilities relative to small size, low power consumption, ingress protection and ease of use, magnetic sensors – and TMR sensor technology in particular – are solving the problem of how to power on or activate battery-operated drug delivery devices.