To Issue 168

Citation: Schmidt P, “Testing Syringes & Injection Devices: Solutions that Boost Efficiency”. ONdrugDelivery, Issue 168 (Jan 2025), pp 86–88.

Peter Schmidt discusses ZwickRoell’s offerings in the arena of testing systems for injectable drug delivery systems, in particular highlighting the advantages of automation for providing reliable, reproducible results.

When testing disposable and prefilled syringes, the smallest influences can change the test results. An error in the quality assurance process can not only lead to disastrous consequences for the quality of the results but also disrupt factory shipments and incur additional costs. Accounting for this is especially critical when using prefilled syringes in autoinjectors.

“Automated processes reduce operator influence and can produce transparent and reliable test results.“

Automated processes reduce operator influence and can produce transparent and reliable test results. Additionally, they significantly increase specimen throughput and reduce the cost to test each specimen. Both are important considerations when it comes to efficiency. With these factors in mind, global market leader ZwickRoell offers various testing solutions to provide results with both semi-automated and fully automated systems.

Figure 1: Sequential testing on a single autoinjector – all results are determined in a single test run.

SEQUENTIAL TESTING: ONE TEST RUN, ONE SPECIMEN, ALL THE RESULTS

Consider an autoinjector – all functions must be tested in the manner in which the patient is expected to use the device.Here, different results must be determined for each user action, from removal of the safety cap to activation, as well as functions that occur after the injection. If each result were to be obtained from a separate test or from different specimens, they would not be comparable, which would have significant implications for the validity and reproducibility of the results. ZwickRoell has therefore developed a testing system that determines all the necessary results in a single run with a single specimen – guaranteeing comparable and reproducible test results (Figure 1).

Figure 2: Serial testing with X-Y table for breakaway and glide force testing.

SERIAL TESTING: TESTING SEVERAL SPECIMENS IN SUCCESSION

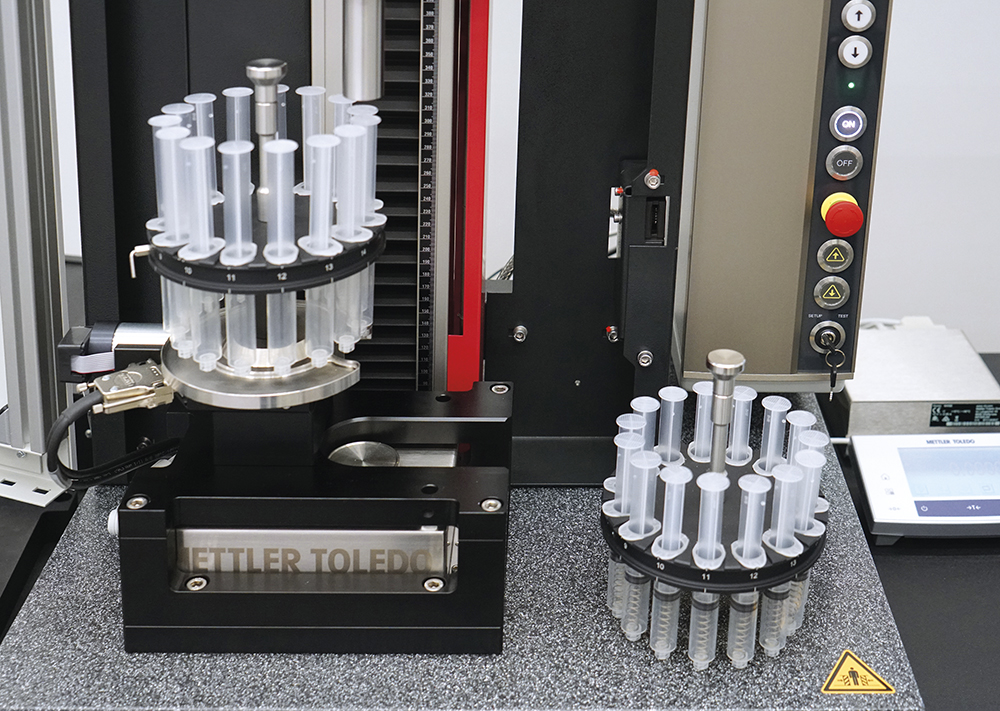

Larger numbers of test specimens, such as syringes or cartridges, can be tested in series and without user influence using quick-load interchangeable magazines. ZwickRoell offers several different magazine solutions, such as the precision X-Y table for 64 specimens (Figure 2) or a rotary magazine for 15 syringes (Figure 3),depending on the respective requirements of the test throughput and the desired modularity of the testing system. All systems are controlled via ZwickRoell’s testXpert testing software with a specimen-specific test programme, always in accordance with US FDA 21 CFR Part 11. With both solutions, operator influence is significantly reduced or eliminated.

Figure 3: The rotary magazine is used to automatically test 15 syringes one after the other; another magazine can be loaded in parallel.

“In order to reduce the test time for multiple syringes, ZwickRoell’s testing machines can be extended to test six to eight specimens simultaneously.”

PARALLEL TESTING: TESTING SEVERAL SPECIMENS SIMULTANEOUSLY

In cases where a drug is administered slowly via a syringe, such as in syringe pumps, individual tests take a comparatively long time. As such, achieving high throughput by testing a batch of syringes simultaneously tends to be an attractive scenario. In order to reduce the test time for multiple syringes, ZwickRoell’s testing machines can be extended to test six to eight specimens simultaneously (Figure 4). The test results for each syringe are recorded individually and clearly displayed in the results matrix of the testXpert testing software.

Figure 4: Eight syringes tested simultaneously, with individual test results and values recorded separately.

“For high test volumes where the capacity of serial solutions has been exhausted, it makes sense to expand the testing machine with a mobile robot system.”

FULLY AUTOMATED TESTING SOLUTIONS WITH INTEGRATED ROBOT

For high test volumes where the capacity of serial solutions has been exhausted, it makes sense to expand the testing machine with a mobile robot system (Figure 5). This complete system guarantees safe and economical testing of autoinjectors, insulin pens or vials with the maximum testing throughput. Depending on the requirements, collaborative robots (smart robots) or industrial robots can be used. Graphical visualisations can be used to display system status in real time via mobile devices such as tablet PCs. Visualisation increases the efficiency of the robotic testing system by reducing idle time. Additionally, the modular design of the robotic testing system enables manual tests to be performed with the machine whenever required.

Figure 5: A robotic system can handle a very high test volume with 24/7 operation.