To Issue 182

Citation: Schroeder J, “Accelerating Patient-Centric Therapies from Development to Delivery”. ONdrugDelivery, Issue 182 (Jan 2026), pp 118–121.

Visit PCI at Pharmapack Paris! – Stand 4F55

Justin Schroeder outlines its product service offering to the drug delivery industry, including sterile fill-finish services, drug-device combination product development and testing, clinical and commercial device assembly, packaging, storage and distribution, among other services.

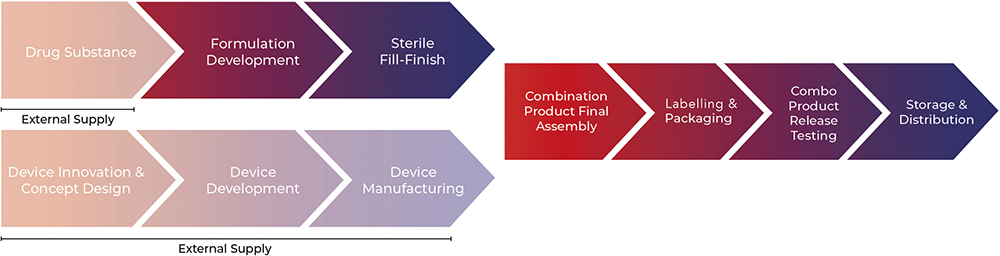

PCI is a CDMO that provides expertise and solutions in sterile fill-finish and specialist final assembly, testing and packaging of advanced drug delivery and drug device combination products. With its seamless, integrated injectable solutions, comprehensive approach and dedication to excellence, PCI provides convenient, easy-to-use and patient-centric therapies throughout clinical trials, product launch and commercial market supply (Figure 1).

Figure 1: Combination product value chain.

One of its key strengths is the flexibility it provides in offering solutions that cater to a diverse, global client base. Whether manufacturing and packaging niche personalised medicines or large, annual-volume treatments, PCI has the global capability and capacity to scale its services to meet specific needs, delivering a streamlined drug-device combination product pathway.

STERILE FILL-FINISH AND LYOPHILISATION

From early clinical batches to global commercial supply, PCI’s aseptic manufacturing and lyophilisation capabilities are trusted across formats and formulations. With nearly three decades of sterile excellence, its scientific expertise and scalable technologies deliver a broad range of small and large molecules, including high-value APIs, such as monoclonal antibodies, oligonucleotides and peptide drug products. Bringing agility and deep technical collaboration to the forefront of sterile product development, PCI’s Pharmaceutical Development Centres of Excellence support phase-appropriate formulation, analytical and process development services offering clients a modality-agnostic, science-driven approach, supporting the strategic transition from vials to syringes or cartridges.

PCI’s scalable vial, syringe and cartridge filling capabilities across Europe and North America are setting new industry standards, while its GMP Annex 1-compliant technologies deliver quality at every stage. Flexible infrastructure supports both small- and large-scale supply, with maximum batch sizes for prefilled syringes (PFSs) ranging from 2,000 to 300,000, providing a strategic pathway from development to commercialisation for a streamlined sterile supply chain.

ADVANCED DRUG DELIVERY AND DRUG-DEVICE COMBINATION PRODUCTS

Driven by innovation and patient-centricity, PCI’s design and development expertise, combined with its device-agnostic assembly and advanced clinical and commercial packaging capabilities, offers flexible solutions for a diverse portfolio of conventional and specialty injectable drug delivery devices. Tailored to unique design, development and manufacturing needs, PCI offers a complete range of capabilities, services and expertise, including:

- Expert design process focused on human factors engineering and technical functionality

- Packaging designs optimised for manufacturability, scalability, automation and sustainability

-

End-to-end drug-device combination services including:

– PFS assembly

– Needle safety-system assembly and precision labelling

– Pen, autoinjector and on-body injector final assembly

– Integrated side- or top-open cartons

– In-process functional testing and final release

– Serialisation

– Cold-chain storage and distribution.

EXPERT ADVICE FROM DEVICE STRATEGY TO PACKAGING DESIGN AND SUSTAINABILITY

With a global network of experts, PCI provides guidance at critical time points to assist its customers in developing an optimised, patient-centric drug-device combination product. Its rich experience can help determine the best device container and strategy for a drug product and patient population. From the use of established well-accepted platforms with regulatory approval as part of a drug-device combination product, which may be deemed a lower risk approach for a new development programme, to a more innovative approach that may be deemed more attractive for specific patient populations compared with more traditional and readily available platforms.

“ITS DEDICATED TEAM OF IN-HOUSE DESIGN SPECIALISTS DELIVERS INSIGHTFUL PACKAGING DESIGN AND PRACTICAL KNOWLEDGE TO DELIVER DIFFERENTIATED, SUSTAINABLE AND COST-EFFECTIVE PACKAGING SOLUTIONS.”

PCI’s pharmaceutical packaging design department provides an innovative and value-added service. Its dedicated team of in-house design specialists provide insightful packaging design and practical knowledge to deliver differentiated, sustainable and cost-effective packaging solutions. Working with its client partners as early as possible during the clinical trial stage, PCI’s design department, together with a cross-functional network of experts in sterile drug product manufacturing, engineering, operations and approved vendors, develops expert design processes focused on human factors engineering and technical functionality, delivering optimised designs for manufacturability, scalability and automation. This seamless solution ensures that key considerations are addressed at the right time, leading to both cost and time efficiencies and ultimately ensuring a swift speed to market.

“WITH TRUE CUSTOMER FOCUS AND FLEXIBILITY AT THE CORE OF ITS DRUG-DEVICE ASSEMBLY AND PACKAGING CAPABILITIES, PCI’S DEVICE-AGNOSTIC TECHNOLOGIES CAN ADAPT TO THE UNIQUE REQUIREMENTS OF VARYING PLATFORMS AND BESPOKE DEVICE REQUIREMENTS FROM CONCEPT TO COMMERCIALISATION.”

SCALING FROM CLINICAL TO COMMERCIAL SUPPLY

With true customer focus and flexibility at the core of its drug-device assembly and packaging capabilities, PCI’s device-agnostic technologies can adapt to the unique requirements of varying platforms and bespoke device requirements from concept to commercialisation. For example, its specialised clinical and low-volume commercial autoinjector assembly lines provide a multi-platform autoinjector solution with the added capability to assemble and label needle safety-system platforms, making it the ideal technology for development studies, clinical trials and niche orphan drugs.

Providing an integrated, scalable solution, PCI’s mid-to-high volume commercial assembly technologies are also able to accommodate multiple drug-device combination product types at a larger scale for later-stage clinical programmes, product launch and ongoing commercial market supply. Supporting true customisation, its technologies can easily and cost-effectively be tooled for new autoinjector change parts, allowing PCI to respond quickly and efficiently to technological changes and future innovation.

STRATEGIC INVESTMENTS TO MEET GLOBAL DEMAND

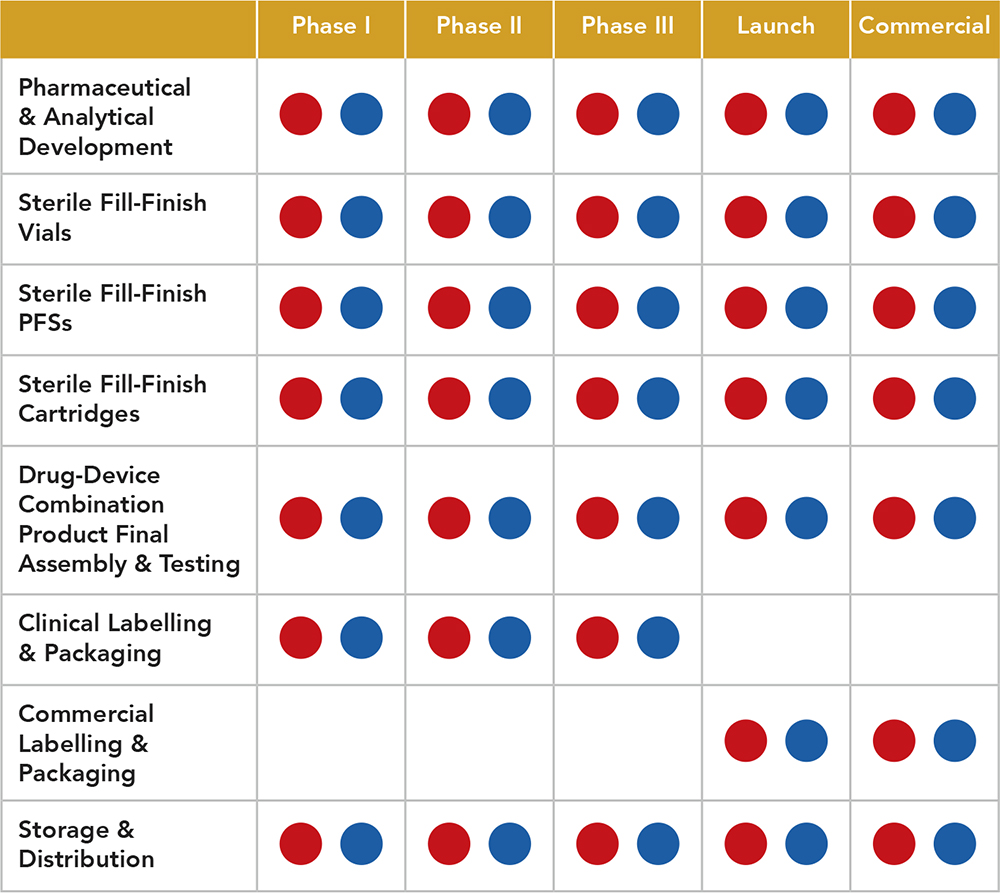

Guided by delivering flexible, future-ready solutions that empower its clients to meet patient needs, PCI continues to make strategic investments to expand its global sterile fill-finish, device assembly, testing and packaging network (Table 1).

Table 1: Availability of PCI’s services ( US 🔴, EU 🔵).

San Diego, CA, US

PCI has acquired of Ajinomoto Althea, a CDMO with proven expertise in clinical and commercial sterile vial, PFS and cartridge filling. This strategic acquisition has expanded PCI’s capabilities, capacities and technologies, including isolator-based syringe filling lines for the aseptic manufacturing of biologics, including messenger RNA, monoclonal antibodies, lipid nanoparticles, oligonucleotides, peptides and other complex modalities. This increased capacity can fulfil the needs for traditional PFSs and PFSs with advanced needle safety-system technologies, as well as PFSs for autoinjectors.

León, Spain

Strengthening PCI’s clinical-to-commercial-scale PFS filling solutions in Europe is another important step and, as part of a US$25 million (£19 million) investment plan, it is investing in new high-speed isolator-based PFS and cartridge technology at its European sterile fill-finish facility in León. The new fully automated PFS filling technology can deliver up to 12,000 units per hour, with a maximum batch size of 300,000 syringes.

Ireland

In 2024, PCI acquired a 90,000 sqft pharmaceutical packaging facility in Dundalk providing commercial-scale injectable drug-device assembly and packaging together with ambient and refrigerated storage. Continuing the expansion, a new 80,000 sqft facility at its CityNorth campus in Stamullen is nearing completion. This facility will add further final assembly, labelling and packaging capacity for vials, PFSs and drug-device combination products, including autoinjectors and pens.

Rockford, IL, US

In the US, PCI’s infrastructure investment includes two new large-scale facilities at its Rockford campus. These state-of-the-art facilities will house over 25 dedicated suites with multi-format lines for clinical- and commercial-scale assembly and packaging of PFSs, autoinjectors, vials and pen-cartridge combinations. They incorporate extensive ISO-standard product-testing capabilities and premium top-load carton technology.

With the aim of accelerating advanced drug delivery and drug-device combination products through clinical trials to commercialisation as efficiently and cost-effectively as possible, one facility will support the whole development lifecycle, from clinical to commercial final assembly and packaging, of an injectable drug product under one roof. This approach combines efficiencies and streamlines drug product journeys from their clinical stages through launch and commercialisation. Both facilities will be GMP ready early 2026.

SEAMLESS, ACCELERATED SUPPLY CHAIN SOLUTIONS

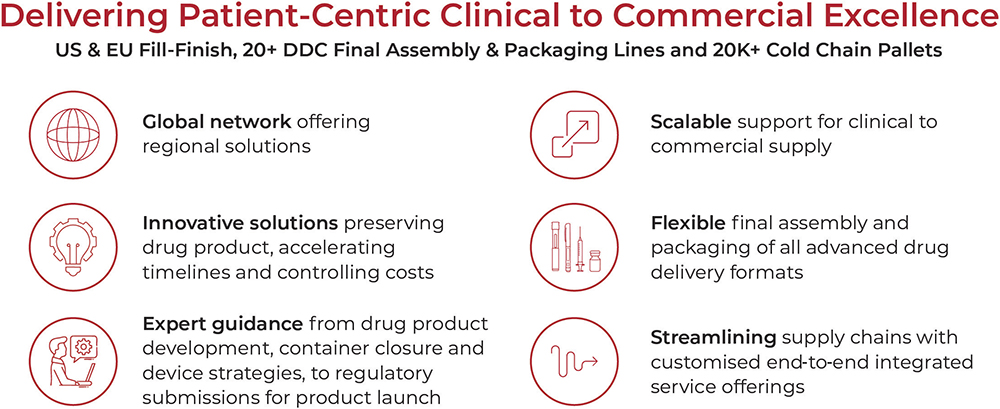

PCI’s highest priority is ensuring that life-changing medicines reach those who need it most. As an integrated global CDMO, it is an expert in manufacturing, packaging and supply chain considerations, harnessing its experience and expertise to deliver seamless solutions (Figure 2). PCI provides sterile fill-finish and lyophilisation solutions from development to commercialisation, together with custom assembly, testing and packaging solutions for sterile injectables in unified, integrated environments. This approach allows for streamlined knowledge sharing and communication between teams, ensuring that the drug-device combination product packaging is optimised for product, patient and production.

Figure 2: PCI’s value-added service offering.

Supporting a quick-to-patient supply chain, PCI’s scalable, device-agnostic technologies, coupled with its extensive, readily available assembly and test tooling for the most common device platforms, removes the need for a lengthy project lead time of up to six months for new tool sets and provides significant time and asset cost savings. With in-house laboratories, it provides a range of packaging and analytical services to support development projects, as well as the clinical and commercial supply of medicines globally.

From product ID testing, method transfer, release and stability testing, through functional autoinjector system testing, to ISO standard testing to assess key performance metrics such as cap removal force, activation force, dose accuracy and injection time, PCI ensures that its clients’ therapies meet regulatory guidelines and are ultimately safe for patient use. PCI offers expertise and solutions tailored to the unique demands of its customers’ development programmes and the patients they serve. Its integrated solutions for drug delivery, comprehensive approach and dedication to excellence positions it as a leader in this rapidly evolving industry.