Citation: Wierckx C, Guillet A, “Adding Value to Prefilled Syringes: Safety and Connectivity”. ONdrugDelivery Magazine, Issue 101 (Oct 2019), pp 70-73

Chantal Wierckx and Arnaud Guillet provide an update on Newguard™, Biocorp’s integrated safety device for prefilled syringes, and explore the possible advantages connectivity can bring in the context of traceability for anti-counterfeiting, in clinical trials and in vaccination campaigns.

“Wireless technologies such as Wi-Fi, Bluetooth low energy (BLE) and near field communication (NFC) are now being increasingly used in healthcare.”

The prefilled syringes (PFS) market keeps growing according to the estimates given by various market forecasts, now reaching a global value of around US$5 billion (£4 billion). The main driver underlying the observed trend is the growth of the list of injectable products with more biologic products than ever being approved by regulatory bodies. A wider geographic coverage of PFSs is also driving the growth of the market in emerging countries.

In addition to this, prefilled syringes offer multiple benefits to pharmaceutical companies, healthcare professionals (HCPs) and end-users to treat or prevent illness. This includes being ready to use, which provides a quick way to inject medications in an emergency. The fact that no drug needs to be transferred from a vial to a delivery system is also beneficial as it is easy to use and leads to a reduction in dosing errors and potential contamination. Furthermore, the prefilled syringes contain the precise quantity to be delivered, resulting in a big reduction in wasting valuable product.

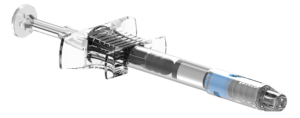

Figure 1: Newguard™ is a reliable, integrated safety device compatible with standard prefilled syringes.

INTEGRATING A SAFETY DEVICE

Safety is an important consideration with prefilled syringes. Any person handling sharp devices such as needles are exposed to injuries that could lead them to being infected with blood-borne pathogens. To meet this need, Biocorp has developed Newguard™, which is a reliable, integrated safety device compatible with standard prefilled syringes designed to prevent accidental needlestick injuries and any unintended re-use (Figure 1). Its user benefits include:

- Ease of use

- Passivity of the system

- Guarantee of safety before, during and after the injection

- Compact size for optimal storage

- Transparency to correctly see the needle tip (Figure 2).

Figure 2: The needle-safety mechanism

of Newguard™ is transparent to allow

the tip to be seen.

In terms of manufacturing benefits, Newguard™ meets the requirement to fit the standard PFS nests and tubs, it is compatible with various sterilisation processes, fits the conventional packaging formats and respects the conventional filling equipment and processes.

Adding a safety device to a syringe may have significant consequences for the manufacturer and lead to the need for changes of the industrial production and filling processes of the PFS. However, Biocorp took this requirement into consideration during its development, and made sure that the assembly of the Newguard™ safety system together with a PFS doesn’t require any specific investment. For this reason, this product is ideal for companies that haven’t invested yet in safety systems but need simple solutions to implement with low capital expenditure requirements.

INTRODUCING CONNECTIVITY

The move to e-health began a while ago when providers started to look for ways to diagnose, monitor and treat patients with connected medical devices. Wireless technologies such as Wi-Fi, Bluetooth low energy (BLE) and near field communication (NFC) are now being increasingly used in healthcare.

Figure 3: Mallya™ is a smart sensor that turns conventional injection pens into connected devices.

Biocorp is very proud to have been at the forefront of developing drug delivery device applications of these cutting-edge technologies and is now leading the way delivering connected solutions to pharma. For example, the Biocorp Mallya™ device (Figure 3) is a smart sensor that turns conventional injection pens into connected devices by recording key treatment information (selected dose, date and time of injection) and sending the data in real time to a dedicated mobile application. Biocorp recently obtained a CE0469 mark for Mallya™ as a medical device class IIb, with the first launch being scheduled for insulin pens. It is also easy to adapt Mallya™ to other pen applications such as fertility, weight loss, multiple sclerosis, growth hormone and Parkinson’s disease. Furthermore, with innovative technological changes, more medical devices such as connected infusion pumps, glucose monitors, inhalers, blood pressure monitors or thermometers will be able to generate, collect, analyse or transmit data.

However, this important connectivity feature for standard prefilled syringes is still missing. There is no way to gather key information automatically about the appropriate usage and delivery of the drug in a PFS format. It would be useful to know – for both the physician and the patient – whether the syringe was correctly used, if the drug was totally delivered, and the time and date of injection.

USING CONNECTIVITY TO IMPROVE TRACEABILITY

“Adding traceability to a PFS could play a key anti counterfeiting role, minimising the spread of fake medicines. Other benefits include monitoring the delivery of expensive biologics, ensuring the efficacy of vaccination campaigns and improving the efficiency of clinical trials.”

Many pharma companies are looking for innovative technological solutions to ensure the protection and traceability of products, to identify fake products and to secure the supply and distribution chain.

Biocorp is currently exploring the possibilities offered by tracing PFS devices using the Unique Device Identification (UDI), which can be included into the readable data of the connected device. The American and European Medical Devices Regulation introduced the need for a device traceability system based on UDI to allow for the unambiguous identification of a specific device on the market.

BENEFITS OF PROVIDING TRACEABILITY

Adding traceability to a PFS could play a key anti-counterfeiting role, minimising the spread of fake medicines. Other benefits include monitoring the delivery of expensive biologics, ensuring the efficacy of vaccination campaigns and improving the efficiency of clinical trials.

Anti-Counterfeiting

A UDI includes a device identifier (DI) – a static part of the UDI number that identifies the specific device among a product range. It also includes any applicable production identifiers (PIs) such as lot number, serial number, manufacturing date and expiration date. Such identifiers could also be linked to key information and documents such as certificates, declaration of conformity and technical documentation. A companion software application linked with the connected syringe could potentially detect if the PFS is on the administration list or may be part of a possible counterfeit medicine.

Delivery of Drugs

It would be particularly useful to know if biologic drugs are delivered successfully as they are very expensive, especially for pharma companies and payers who have a direct incentive to know if a drug has been correctly administered. Medication errors happen too often, even with treatments administered by professionals. For each injection, careful attention must be paid to ensure it’s the right patient, the right drug, the right time, the right dose and the right route. Therefore, connected technology would help decrease errors in administration as patients can be better monitored and linked with the drug administered. This leads to more efficacious therapeutics and better cost control for payers.

Vaccination Campaigns

“With a connected PFS, pharmaceutical companies can consider alternative study designs, such as organising clinical trials in real-life conditions. Instead of bringing patients into clinical facilities, they could provide a batch of connected PFS and remotely monitor treatment delivery at home.”

In terms of vaccination campaigns, a connected PFS would significantly help to ensure traceability. Mass immunisation campaigns pose specific traceability challenges, due to their objective of immunising large populations over a short period of time and the fact they are often conducted outside the normal healthcare setting. As a result, the coverage of highly recommended vaccines is frequently inadequate and incomplete, which leaves significant portions of the population at risk. Instead, with connected PFSs, immediate upload of vaccine data becomes possible, directly filled in to an application associated with the patient’s name. This would enable HCPs to maintain thorough and up-to-date vaccination records for each patient and avoid missed or incomplete immunisations. The data collected could feed directly into vaccine management systems or patient’s electronic health records (EHR).

Clinical Trials

There is also an evident opportunity for connectivity in collecting dose delivery data during clinical trials and observational studies to better follow and understand treatment efficiency results and potential underdosage incidents. Clinical trials may compare a new medical approach: with a standard one that is already available; with a placebo that contains no active ingredient; or with no intervention. Some clinical trials compare interventions that are already available. When a new product or approach is being studied, it is not usually known whether it will be helpful, harmful or no different than available alternatives. The investigators try to determine the safety and efficacy of the intervention by measuring certain outcomes in the participants.

The automated detection and collection of the key treatment delivery information would be a real advantage in this situation. This would save time and avoid loss of data, incomplete records and gaps in the information collected. The collection and reporting of treatment delivery information and the aggregation of data into the clinical file would be much simpler and faster. Thus, the solution is likely to reduce the number of clinical operators involved in the study, making it more cost effective.

With a connected PFS, pharmaceutical companies can consider alternative study designs, such as organising clinical trials in real-life conditions. Instead of bringing patients into clinical facilities, they could provide a batch of connected PFS and remotely monitor treatment delivery at home. If some issues with treatment compliance are observed, the clinical operators can quickly interact with patients to remedy the situation and put them back on track. Studies in real-life conditions can help pharma companies identify all the factors that negatively impact drug efficacy and provide the appropriate services and corrective measures before commercial launch. They could also give precious information for potential post-approval/Phase IV studies.

DEVELOPING A CONNECTED PREFILLED SYRINGE

Earlier this year, Biocorp put together its teams to generate innovative ideas that meet the existing needs for an e-PFS. Team members care passionately about doing work that helps others, and commit to ensuring a high level of quality during the design, development and manufacturing phases of a new product. Biocorp has the strength and the ability to adapt to ever-changing techniques and constraints maintaining a keen focus on delivering user-friendly products with maximum simplicity.

To be successful, a connected PFS must meet various functional requirements. It must collect essential information such as injection completed, time and date, type of drug, its batch number and expiration date. In addition, it must meet user requirements such as ergonomic handling, being intuitive and leveraging existing prefilled syringe features. On the manufacturing side, the components required for adding connectivity must be validated and fit the conventional nest and secondary packaging. Moreover, similar to the Newguard™ safety device, the connectivity components should not interfere with the filling line process.

CONCLUSION

Biocorp is planning to commercialise connectivity features for PFS as early as the beginning of 2020. More detailed information will be revealed during the product launch at the PDA Universe of Pre-Filled Syringes & Injection Devices conference in Gothenburg, Sweden, on October 21, 2019, and during the event on October 22-23, 2019.

Biocorp will then continue to extend its range of products and intends to supply combined safety and connectivity solutions “all-in-one” for standard prefilled syringes to serve the needs of our customers around the globe, for the benefit of their patients.