To Issue 152

Citation: Neale J, “Technological Advancements to Overcome Viscosity Challenges for Injectable Devices”. ONdrugDelivery, Issue 152 (Oct 2023), pp 57–60.

Joe Neale explores injectable drug development, delving into the intricacies of how technology is advancing to meet the challenges of administering complex formulations, enabling a more positive patient experience, promoting dosing compliance and maximising the benefits of these essential medicines.

“The healthcare landscape is continuously shifting to develop medicines and treatments that cater more effectively to patient needs, manifesting in an increased demand for self-administered therapeutics.”

Injectable drug delivery stands as a cornerstone of modern medical practice, being essential for numerous medical interventions. From vaccinations to intricate biologic therapies, parenteral administration and injectable devices have revolutionised patient care, allowing for precise dosing and targeted treatment strategies.

A notable trend in the pharmaceutical industry in recent years is the surge in the number of therapeutics in development that require parenteral delivery. More than 50% of new chemical entities in the drug development pipeline are now parenterally administered biologics.1 Although the rising demand for biologics holds promise to produce innovative and life-changing medicines, their large molecular composition, and therefore high viscosity, presents potential complications for their injectability.

Complications in administering viscous formulations are frequently due to traditional injectable devices being unable to deliver these medicines through a needle fine enough to be acceptable to the patient. This issue not only affects patient comfort, but also risks inaccurate dosing, low adherence and poor treatment efficacy when delivering high-viscosity therapeutics.

Challenges surrounding high-viscosity parenteral administration are further intensified by a rising preference for self-administered therapeutics and the usability advantages of autoinjectors. The healthcare landscape is continuously shifting to develop medicines and treatments that cater more effectively to patient needs, manifesting in an increased demand for self-administered therapeutics. This is further reflected in the significant growth of the global self-injection devices market, which is predicted to increase from USD$6.6 billion (£5.3 billion) in 2021 at a compound annual growth rate of 5.7% to 2030.2

Addressing the growing desire for patient-centric administration options and overcoming challenges surrounding high-viscosity formulation requires a delicate balance of innovation and scientific understanding to provide a solution that ensures accurate and consistent dosing, as well as patient compliance.

“Synergy between technological innovation and pharmaceutical ingenuity is needed to redefine the administration of viscous formulations.”

ADMINISTRATION CHALLENGES OF VISCOUS FORMULATIONS

Viscosity refers to the internal resistance of a liquid to flow. Highly viscous liquids have a higher resistance to flow due to the presence of large, complex molecules that entangle with each other, leading to stronger intermolecular forces within the liquid. Injectable drug formulations can vary in viscosity depending on factors such as the nature of the API and solvents used; for example, larger API or solvent molecules increase viscosity. Currently, high-viscosity formulations are being developed at an increasing rate – so the technology being developed to facilitate their administration must meet their intricate needs.3

Conventional injection devices consist of short-gauge needles (commonly referred to as standard-gauge needles) and a spring-powered plunger. These devices are effective for administering small molecule medicines but have limitations when administering viscous formulations. The high resistance of the formulation and the thin needle diameter require significant pressure to be applied to the plunger, risking breaking the syringe container, especially when it is made from glass.

Instead, the standard for viscous drug administration has been the use of traditional injectables with broad-gauge needles. These needles enable the delivery of viscous formulations with a force equivalent to non-viscous formulations via a standard-gauge needle. This approach reduces the risk of shattering the syringe container under pressure.

However, despite their effectiveness in preventing breakage, broad-gauge needles can cause significant patient discomfort and pain due to the size of the needle piercing the skin and underlying tissue. Additionally, the emotional distress caused to people with needle phobia can be significantly exacerbated by the large needles needed for injecting highly viscous formulations. Therefore, there is a clear need to devise a solution for the administration of viscous formulations that overcomes the challenges of traditional methods, while also meeting the demand for broader self-administration options.

“Recipharm’s VapourSoft® technology addresses the need for an administration solution that facilitates the passage of viscous formulations through narrow gauge needles without subjecting the broader device to excessive pressure.”

OVERCOMING THE HURDLES OF VISCOUS DRUG ADMINISTRATION

Synergy between technological innovation and pharmaceutical ingenuity is needed to redefine the administration of viscous formulations. Advancements in injection device technology must aim to overcome the various issues posed by viscous formulations and be designed and developed with the following considerations in mind.

Minimised Variability in Dosing

As these formulations resist flow due to internal friction, precise measurement and uniform delivery to ensure that each patient receives the intended dose can be a tough task. Inconsistency in dosing can impact the treatment’s efficacy, raising concerns about whether it achieves desired therapeutic outcomes.

When specific formulations demand a controlled or precise injection speed to optimise absorption or maintain therapeutic levels, even minor deviations in injection speed can result in inconsistent dosing. The potential for injection speed variability is increased with high-viscosity formulations, as non-Newtonian flow and clogging characteristics can complicate administration. Further to this, variation arising from both individual techniques and the requirements of the specific formulation can affect the rate at which a medicine enters the bloodstream within a given timeframe.

This potential inconsistency warrants a closer examination of more refined solutions. By addressing the contributing factors and considering refined strategies, such as standardised injection protocols or technologies that regulate injection speed, the impact on dosing accuracy can be alleviated.

Increased Patient Comfort

Increasing the spring force and using a broad needle gauge are ways to improve the consistency of injection speed, but these solutions also increase the discomfort felt by the patient. Addressing this uncomfortable experience is crucial, as it discourages patients from adhering to their prescribed treatment regimen. This potential non-compliance casts a shadow on the therapeutic effectiveness of the drug, compromising the benefits that could be reaped from the treatment.

As companies look to differentiate their biologic products from one another within the same indication, any benefits that can be achieved through developing a treatment that is more appealing to patients can prove to be commercially advantageous. The development of novel and patient-centric delivery device technologies will be pivotal for meeting both patient and market demands.

Improved Ease of Use

The high pressure required to push the plunger of traditional devices is often impractical for elderly patients or those with dexterity issues, impacting ease of use. The intricacies of achieving accurate dosing and minimising discomfort during administration will often necessitate the expertise of healthcare professionals, adding to the burden on healthcare systems and taking away patient control over their treatment. This dependency on professional intervention makes the administration process more inconvenient and costly, as well as limiting patient autonomy, making self- administration an appealing proposition if the challenges to ease of use can be overcome.

Solutions from Innovation

Innovations in injection device technology are proving to be pivotal in addressing the challenges posed by viscous drug solutions, enhancing patient comfort and ensuring accurate dosing. These advancements not only alleviate the limitations of conventional methods but also open the door to a more patient-centric approach that encourages independence and fosters a positive treatment experience.

VAPOURSOFT® TECHNOLOGY: RESHAPING THE MECHANICS OF DRUG DELIVERY

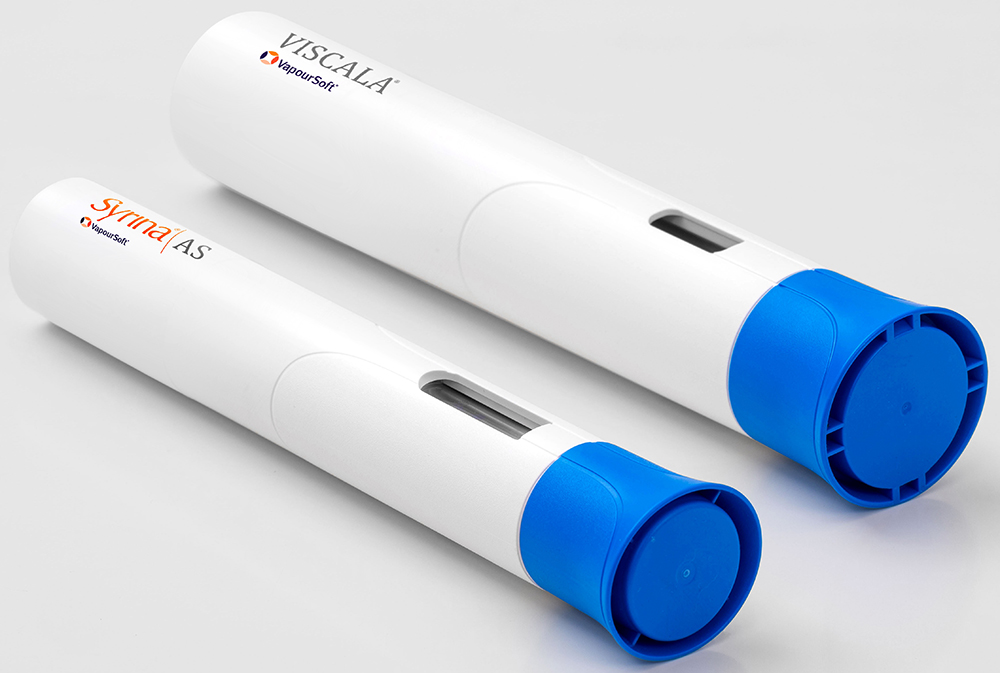

Developed with these considerations in mind, Recipharm’s VapourSoft® technology addresses the need for an administration solution that facilitates the passage of viscous formulations through narrow gauge needles without subjecting the broader device to excessive pressure. VapourSoft is a novel and innovative technology that uses liquefied gas to power drug delivery devices, such as autoinjectors (Figure 1). It introduces altered pressure profiles, fundamentally reshaping the mechanics of drug delivery and overcoming the administration challenges of viscous formulations by enabling smooth and gentle delivery of high-concentration biologics through fine needles.

Figure 1: Autoinjectors powered by VapourSoft technology.

“Collaboration with third-party device experts is crucial in developing user-friendly injectable treatments that can address the administration and manufacturing challenges associated with viscous formulations.”

This advanced technology offers a more evenly distributed pressure application, providing a critical advantage in enabling the administration of viscous formulations with enhanced precision, while also reducing pain and discomfort to patients when injected with conventional syringes. This can improve the patient experience and thereby improve adherence to these therapies by providing a compact, flexible and easy-to-use device.

This departure from the norm has profound implications for drug delivery. Central to the success of this advancement is the noteworthy enhancement of patient comfort. The combination of altered pressure profiles and finer needles culminates in an experience that not only minimises discomfort during the injection, but also alleviates the psychological unease that needle-phobic patients often encounter. This increased comfort level is an important step towards patient-centric care that encourages individuals to take an active role in their treatment journey.

THE IMPORTANCE OF WORKING WITH EXPERTS IN DEVICE DEVELOPMENT

Collaborating with specialist third-party device experts enables drug companies to develop more user-friendly and patient friendly injectable treatments. The value of these experts lies in their ability to provide comprehensive support in surmounting the multifaceted challenges associated with both the administration and manufacture of viscous injectable drug formulations. Their expertise can help navigate the complex terrain of these formulations, ensuring that the final product not only meets technical benchmarks but also aligns seamlessly with patient needs and comfort.

The importance of this collaborative approach cannot be overstated. Pharmaceutical companies can receive considerable benefit from the insights and experience these experts bring to the table, gaining a deeper understanding of the intricacies involved in optimising drug delivery. While technological solutions like VapourSoft® technology are a major facet of addressing the administration of high-viscosity formulations, the expertise of third-party specialists provides a holistic perspective that considers variables beyond technology alone.

HARNESSING INNOVATIONS TO OVERCOME VISCOSITY CHALLENGES

Viscous formulations present unique challenges in the field of injectable drug development. However, technological advancements in injection device technology and container design have paved the way for improved patient experiences and enhanced drug delivery. By overcoming the limitations of traditional devices and optimising the manufacturing process, drug companies can ensure precise and reliable delivery of viscous drugs.

The effect of these technological advancements extends across the dimensions of patient care. From fostering a more comfortable and less distressing injection experience to encouraging patient autonomy through self-administration options, the impact is profound. Moreover, the underlying enhancement in dosing precision and therapeutic efficacy underpins the ultimate objective of patient-centric care – improving the lives and wellbeing of those in need.

Collaboration with third-party device experts is crucial in developing user-friendly injectable treatments that can address the administration and manufacturing challenges associated with viscous formulations. By prioritising patient-centricity and leveraging advancements in technology, drug developers can deliver a better experience for patients, improve dosing compliance and maximise the benefits of these effective medicines.

Discover more about Recipharm’s VapourSoft technology, here: www.recipharm.com/drug-delivery-devices/auto-injectors/vapoursoft-technology.

REFERENCES

- Vhora I et al, “Parenteral Controlled and Prolonged Drug Delivery Systems: Therapeutic Needs and Formulation Strategies” in “Novel Drug Delivery Technologies” (Misra A, Shahiwala A, eds). Springer, Singapore, 2019.

- “Self-injection Devices Market Size, Share & Trends Analysis Report By Product (Autoinjectors, Needle-free Injectors), By Usability (Disposable, Reusable), By Application (Cancer, Pain Management), By Region, And Segment Forecasts, 2022 – 2030”. Research Report, Grand View , Apr 2022.

- Hance J, “Characterisation & Delivery of Ultra-viscous & non-Newtonian Formulations”. Poster, Oval Medical Technologies, Mar 2021.